Beyond Cotton: Exploring Specialty Fabrics and Treatments in Streetwear Manufacturing

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Aug 22,2025

Summary

Discover how streetwear manufacturing is evolving with technical streetwear fabrics, advanced treatments, and sustainable practices. Explore key mens streetwear trends and learn how leading streetwear clothing manufacturers and the best streetwear manufacturers deliver durability, style, and mass production for established brands seeking quality and innovation.

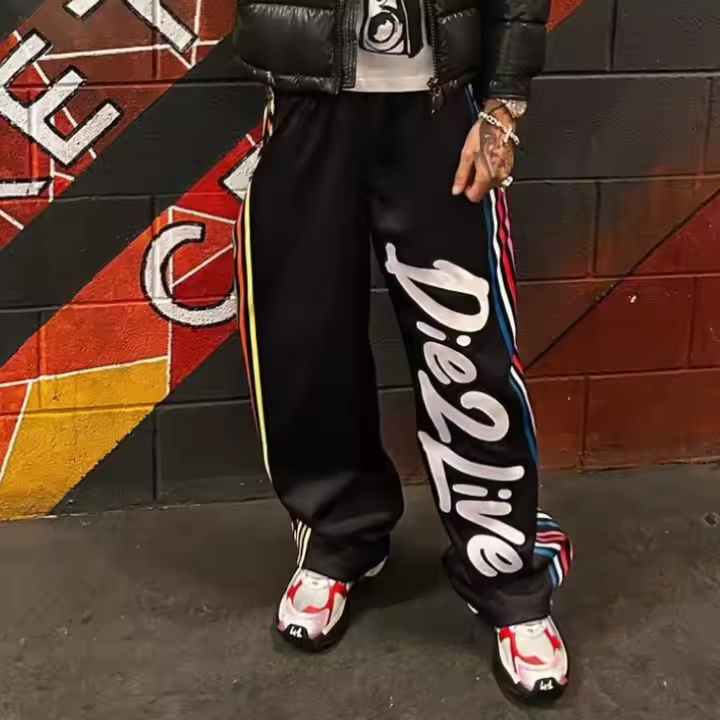

Beyond Cotton: Exploring Specialty Fabrics and Treatments in Streetwear Manufacturing

In the dynamic world of streetwear manufacturing, innovation is not just about design; it's fundamentally about the materials that bring those designs to life. For established streetwear brands, the pursuit of excellence extends far beyond conventional cotton, delving into the realm of technical streetwear fabrics and advanced treatments. These cutting-edge materials and sophisticated finishes are redefining what's possible in urban fashion, offering unparalleled performance, durability, and aesthetic appeal. This deep dive explores how streetwear clothing manufacturers and brands leverage these materials and treatments to elevate their collections and meet the evolving demands of a discerning market, reflecting the latest mens streetwear trends.

What unique properties do technical fabrics bring to streetwear?

Technical streetwear fabrics have become a foundation for next-generation streetwear collections. Their value lies not only in aesthetic innovation, but in their multi-faceted performance attributes that appeal to both designers and end users.

- Enhanced Durability & Abrasion Resistance: Materials such as rip-stop nylon and high-tenacity polyester provide exceptional toughness, allowing garments to withstand daily wear, friction, and urban activities. This is crucial for streetwear where long-lasting quality is an expectation.

- Moisture Management: Technical fabrics engineered with moisture-wicking properties quickly move sweat away from the skin, ensuring the wearer stays dry and comfortable in both crowded cities and active environments.

- Breathability & Temperature Regulation: Many technical textiles are designed for optimal airflow. This not only prevents overheating, but—through innovations like thermoregulatory membranes—helps maintain a stable body temperature across varying climates and seasons.

- Four-way Stretch & Comfort: High-quality stretch knits provide unmatched freedom of movement. Whether skating, biking, or simply navigating urban life, these fabrics retain their shape and comfort through any dynamic activity.

- Distinct Visual Identity: The textures, sheens, and drapes of technical fabrics create a signature look that stands out from traditional cotton. This gives designers a new palette to explore, enabling streetwear clothing manufacturers to push the boundaries of urban aesthetics.

How do manufacturers apply specialized treatments like water-repellency or anti-odor?

Streetwear manufacturing today goes beyond raw material selection; it’s about what manufacturers can do to enhance those materials. Specialized treatments are applied throughout the production process to deliver high-performance and long-lasting garments.

- Water-Repellency (DWR): Durable Water Repellent coatings are applied to fabric surfaces, causing water to bead and roll off. The process—immersion or spraying plus heat curing—ensures resistance to rain and splashes, essential for streetwear outerwear.

- Anti-Odor Finishes: Treatments using silver ions, zinc compounds, or chitosan inhibit bacterial growth, preventing odors even after repeated wears. These can be integrated during dyeing, printing, or as a final finish step.

- UV Protection, Wrinkle Resistance & Stain Release: Modern streetwear clothing manufacturers apply additional finishes that block harmful UV rays, keep garments smooth and sharp, and make cleaning easier—all without sacrificing comfort or appearance.

- Quality Assurance & Consistency: Top streetwear manufacturers for established brands invest in advanced machinery, lab testing, and strict QC protocols to ensure every treatment is effective, durable, and safe for both user and environment.

What are the emerging trends in performance and functional fabrics for menswear streetwear?

Mens streetwear trends are being shaped by rapid innovation in both textile science and sustainability. Key directions include:

- Smart Fabrics & Wearable Tech: Integration of sensors or adaptive membranes allows garments to react to environmental changes or user data (like temperature regulation or movement tracking). While early stage, this field will likely redefine streetwear’s value proposition in the coming years.

- Advanced Fabric Blends: Hybrid textiles—combining natural comfort with synthetic durability and technical function—are increasingly popular. This enables optimized stretch, moisture management, and comfort across diverse streetwear applications.

- Sustainable Manufacturing & Materials: A sustainable clothing manufacturer now sources recycled polyester, organic cotton, hemp, bamboo, and even bio-based fibers (like mushroom or seaweed textiles). Waterless dyeing, closed-loop production, and energy-saving processes are becoming baseline standards for ethical production.

- Comfort & Hygiene Upgrades: New generations of 4-way stretch, more durable antimicrobial treatments, and superior breathability mean performance streetwear is now genuinely wearable all day, every day—without sacrificing its street style DNA.

If you're interested in how global streetwear brands approach manufacturer selection and large-scale production management, we recommend this case study: Unveiling High-End Streetwear Manufacturing: How Groovecolor Empowers Top Global Streetwear Brands . The article explores key criteria for choosing the best streetwear manufacturers and how experienced partners like Groovecolor help established brands maintain quality and efficiency as they scale.

Frequently Asked Questions (FAQs)

What are the key benefits of using technical streetwear fabrics in manufacturing?

Technical streetwear fabrics offer enhanced durability, superior moisture management, improved temperature regulation, and increased comfort through properties like four-way stretch. They also contribute to a modern aesthetic, allowing streetwear manufacturers to create highly functional and stylish garments that stand out in the market.

How do streetwear clothing manufacturers ensure the effectiveness of specialized fabric treatments?

Manufacturers ensure effectiveness through precise application methods, such as immersion or spraying, followed by controlled curing processes to bond the treatment to the fibers. Rigorous quality control, including advanced machinery and laboratory testing, is crucial to verify the durability and efficacy of treatments like water-repellency, anti-odor, and UV protection.

What role does a sustainable clothing manufacturer play in the development of new streetwear?

A sustainable clothing manufacturer leads by adopting eco-friendly materials like recycled polyester and organic cotton, and implementing production processes that reduce environmental impact. These actions not only appeal to modern consumers but also set new standards for quality and ethics in streetwear manufacturing.

Why should established brands seek out the best streetwear manufacturers for technical fabrics?

Established brands choose the best streetwear manufacturers for their deep expertise with technical fabrics, robust quality control systems, and ability to deliver consistency at scale. This ensures each collection meets the highest standards of performance and style demanded in today's mens streetwear trends.