Beyond the Basics: How Established Streetwear Brands Choose Sweatshirt Manufacturers for Scalable Growth in 2025

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Dec 27,2025

Summary

Elevate your established streetwear brand by choosing the right sweatshirt manufacturer in 2025. This guide covers OEM vs. private label, heavyweight French terry, cut and sew, vintage wash techniques, and quality control. Learn how a strategic manufacturing partner like Groovecolor scales production, ensures quality with ISO 9001 and AQL standards, and drives global growth for US and EU markets. Unlock the secrets to scalable, high-quality streetwear manufacturing.

Beyond the Basics: How Established Streetwear Brands Choose Sweatshirt Manufacturers for Scalable Growth in 2025

In the ever-evolving landscape of streetwear, a meticulously crafted sweatshirt is far more than a simple garment; it is a declaration of brand ethos and a canvas for forging profound emotional connections with consumers. With the market projected to reach a staggering $637.14 billion by 2032 [1], the selection of the right manufacturing partner has become a defining strategic imperative for established brands seeking scalable growth. This comprehensive guide delves into the critical considerations for choosing a sweatshirt manufacturer in 2025, covering everything from navigating the complex decision between OEM and Private Label, to the deep science of fabrics, the mastery of sophisticated manufacturing techniques, and the implementation of rigorous quality control protocols. This article aims to provide mature streetwear brands with a holistic framework for evaluating and selecting a manufacturing partner capable of meeting their exacting demands for quality, innovation, and scalability, thereby ensuring their continued success and relevance on the global stage. The journey from a promising streetwear label to a globally recognized brand is paved with countless decisions, but few are as consequential as the choice of who will manufacture your products. This decision will impact everything from the tactile experience of your garments to your ability to scale operations, maintain ethical standards, and ultimately, build a lasting legacy in the fiercely competitive world of fashion.

Key Takeaways for Established Streetwear Brands

Market Strategy

Production Model

Fabric Selection

Manufacturing Craftsmanship

Quality Control

Partnership

1. The Sweatshirt as a Cornerstone of Street Culture

In the vast tapestry of streetwear, the sweatshirt and hoodie occupy an unshakeable, central position. They have long transcended their purely utilitarian origins, evolving into powerful cultural symbols and mediums for self-expression that resonate across generations and geographies. From the B-boys of the Bronx in New York, to the Grime music scene on the streets of London, to the skateboarding culture of Paris, the sweatshirt has witnessed and shaped every pulse of global youth culture. It has been the uniform of rebellion, the canvas of artistic expression, and the comfortable companion of countless cultural movements. For an established streetwear brand, a sweatshirt is a concentrated embodiment of its design language, values, and brand narrative. It is a mobile canvas that, through unique silhouettes, innovative fabrics, and compelling graphics, builds a profound emotional resonance with its target audience. The sweatshirt tells a story, and that story must be authentic, compelling, and consistently told through every stitch and seam.

The cultural significance of the sweatshirt cannot be overstated. It emerged from the athletic fields and locker rooms of early 20th century America, but its journey into the heart of fashion is a testament to its versatility and the power of subcultures to redefine mainstream aesthetics. Hip-hop artists in the 1980s adopted the hoodie as a symbol of urban identity, while skaters on the West Coast made it an essential part of their anti-establishment uniform. In the UK, the hoodie became intertwined with the Grime scene, representing a raw, unfiltered form of self-expression. In France, it became a staple of the burgeoning skate and street art scenes in cities like Paris and Lyon. This rich cultural heritage means that when a brand creates a sweatshirt, it is not just making a piece of clothing; it is contributing to an ongoing cultural dialogue. The choice of manufacturer, therefore, is a choice about how that dialogue will be shaped, the quality of the message, and the integrity of the brand's voice.

However, as a brand transitions from its nascent stage towards maturity and scale, the challenges it faces grow exponentially. Consumer expectations for quality are higher, demands for design uniqueness are more stringent, and scrutiny of a brand's sustainability commitments is more intense than ever before. The modern consumer is educated, discerning, and increasingly values transparency and ethical production. Against this backdrop, selecting the right manufacturing partner is no longer merely an operational decision; it is a strategic undertaking that determines whether a brand can maintain its market leadership and achieve sustainable growth. An ideal manufacturer is not simply an order executor but should be a strategic partner capable of understanding the brand's vision, providing technical solutions, and growing alongside the brand. This guide will delve into every critical link that established streetwear brands must consider when choosing a sweatshirt manufacturer in 2025, aiming to provide a clear roadmap to help brands build a supply chain that is both robust and agile, ready to meet the challenges and opportunities of the future. The stakes are high, and the margin for error is slim. Making the right choice can propel a brand to new heights, while a misstep can lead to costly delays, quality issues, and irreparable damage to brand reputation.

2. The 2025 Streetwear Market Landscape: Trends and Insights

To make informed manufacturing decisions, one must first possess a deep understanding of the market environment. The streetwear market is undergoing unprecedented growth and transformation, revealing immense commercial potential and increasingly sophisticated consumer demands. According to authoritative data from Fortune Business Insights, the global streetwear market size reached $347.14 billion in 2024 and is projected to grow to $371.09 billion in 2025. More strikingly, the market is expected to reach a staggering $637.14 billion by 2032, growing at a Compound Annual Growth Rate (CAGR) of 7.89% [1]. This data clearly indicates that streetwear is not a fleeting trend but a continuously expanding and vibrant mainstream market with deep roots in global culture. Within this, the Asia-Pacific region dominates with a 36.27% market share, while the U.S. market is projected to reach $102.61 billion by 2032, demonstrating robust growth potential [1]. The European market, particularly in fashion-forward countries like France, the UK, and Germany, also represents a significant and growing opportunity for brands with strong design credentials and a commitment to quality.

Against this backdrop of macro-level growth, several key trends are reshaping the market and directly influencing brand choices regarding manufacturers. Understanding these trends is not optional; it is essential for any brand that wishes to remain relevant and competitive. The Rise of Sustainability: Heightened environmental awareness is driving consumers towards brands committed to environmental stewardship. This is no longer a niche concern but a mainstream expectation, particularly among younger demographics who form the core of the streetwear consumer base. From using eco-friendly fabrics like organic cotton and recycled polyester, to adopting water-saving and energy-efficient production processes, sustainability has become crucial for brands to build credibility and attract loyal consumers. Whether a manufacturer possesses relevant certifications (such as GOTS, GRS) and sustainable production capabilities has become a vital criterion for brand evaluation. Brands that fail to address this trend risk alienating a significant portion of their potential customer base and facing increasing scrutiny from media and advocacy groups.

Vintage Aesthetics and Nostalgia: The resurgence of 90s and Y2K styles has sustained the popularity of vintage-style sweatshirts, particularly those featuring special wash treatments (like acid wash, stone wash) and oversized fits. This trend speaks to a longing for authenticity and a connection to the perceived golden eras of streetwear and hip-hop culture. Brands need to seek out manufacturers who are masters of vintage craftsmanship and can precisely replicate nostalgic textures without compromising on modern quality standards. The ability to achieve a genuinely "worn-in" look that feels authentic rather than artificial is a highly specialized skill that separates premium manufacturers from the rest. Gender Fluidity and Inclusivity: An increasing number of consumers are seeking apparel that transcends traditional gender norms. Gender-neutral and fluid designs, such as relaxed cuts and unisex styles, are becoming increasingly important. This requires manufacturers to offer flexible pattern development and size ranges to cater to a more diverse consumer base. Brands that embrace inclusivity not only tap into a growing market segment but also align themselves with progressive social values that resonate deeply with the streetwear community.

These trends collectively point to one conclusion: the future of the streetwear market will belong to brands that can seamlessly integrate quality, innovation, and responsibility. Therefore, when selecting a manufacturer, brands must look beyond simple cost considerations and seek partners whose technology, craftsmanship, and values are highly aligned with the brand's future direction. A manufacturer who understands these market dynamics and can proactively offer solutions to address them is an invaluable asset. The right partner will not just react to your requests but will anticipate your needs and help you stay ahead of the curve. This proactive approach to partnership is what distinguishes a mere supplier from a true strategic ally.

3. Manufacturing Partnership Models: OEM vs. Private Label

Having established the market direction, the first major decision a brand faces is selecting the appropriate production model. The two most mainstream models are Original Equipment Manufacturer (OEM) and Private Label. For an established streetwear brand, understanding the deep-seated differences between these two models is of paramount importance. The choice made here will fundamentally shape the brand's identity, its competitive moat, and its long-term trajectory in the market. It is not merely a logistical choice but a strategic declaration of the brand's core values and its commitment to its customers. This decision will echo through every product you release and every interaction you have with your consumer base.

OEM (Original Equipment Manufacturer): Deep Customization for Brands Seeking Unique Designs and Complete Control. The OEM model involves the brand providing detailed design specifications and a technical package (Tech Pack), with the manufacturer producing entirely according to these specifications. This is the most direct path to realizing a brand's unique vision and creating products that are truly differentiated in the marketplace. As Groovecolor points out in its in-depth analysis, the OEM model grants brands complete creative freedom [2]. You can dictate everything from the yarn composition and GSM of the fabric, to the specific Pantone color codes, to precise dimensional specifications and complex sewing constructions. For streetwear brands, this means the ability to create truly one-of-a-kind products, whether it's a special drop-shoulder design, a boxy cut, or unique graphic applications like puff print or distressed effects. The level of control is unparalleled, allowing the brand's creative vision to be translated into a tangible product without compromise. This is the path for brands that see their products as art and their manufacturing partner as a collaborator in that artistic process.

Furthermore, under the OEM model, brands can set and enforce stringent quality standards that reflect their commitment to excellence. Experienced OEM manufacturers like Groovecolor possess the technical prowess and infrastructure to translate complex designs into high-quality finished garments with precision and consistency. They can control material quality from the source, working directly with fabric mills to develop custom textiles, and implement monitoring at every stage of production, ensuring the consistency and durability of the final product. This level of oversight is simply not possible with private label arrangements. Mature OEM manufacturers typically boast robust production capacity and optimized production lines, enabling them to handle large-volume orders efficiently. This is crucial for established brands that need to meet peak market demand, restock quickly, or execute global launches across multiple regions simultaneously. Scaled production also yields cost efficiencies, reducing the per-unit cost of products and improving profit margins over time.

Private Label: An Efficient Solution for Brands Seeking Rapid Market Entry. The Private Label model involves a manufacturer pre-developing and producing a range of "blank" or basic garment styles. Brands can then add their own branding (such as neck labels, hang tags) and simple customizations (like prints) to these existing styles. Since it bypasses the design and development process from scratch, the Private Label model can significantly shorten the time from concept to market. This is a notable advantage for brands looking to quickly test market response or capitalize on fleeting trends without committing significant resources to product development. Private Label typically offers lower Minimum Order Quantities (MOQs), reducing a brand's upfront capital investment and risk in inventory. This allows brands to launch a new collection or test a new product line with less capital, making it an attractive option for startups or for established brands looking to experiment with a new category outside their core competency.

Strategic Decision: Choosing the Right Model for Your Brand. For startups or sub-lines looking to quickly test the market, the Private Label model offers a low-risk shortcut that can be valuable in the early stages of brand development. However, for an established streetwear brand, whose core competitiveness lies in its unique design language and superior product quality, this is precisely where the Private Label model falls short. Private Label products lack uniqueness; multiple brands may sell garments that look similar, which dilutes brand value and damages the brand's unique positioning in the minds of consumers. In the streetwear world, where authenticity and originality are paramount, this can be a fatal flaw. Therefore, for established streetwear brands committed to building long-term brand equity, pursuing design innovation, and achieving superior quality, OEM is the only and inevitable choice. While it requires brands to invest more resources in design and development, the return is complete control over brand image, guaranteed product quality, and the construction of a moat that competitors find difficult to replicate. Manufacturers like Groovecolor even offer flexible OEM services, allowing established brands to test highly innovative designs with relatively low MOQs (such as 50-100 pieces). Once market validation is successful, they can quickly transition to large-scale production, perfectly combining market agility with scalability [2]. This hybrid approach offers the best of both worlds for brands ready to take their production to the next level.

4. Fabric Science Demystified: The Foundation of an Exceptional Sweatshirt

Fabric is the cornerstone that determines the quality, comfort, and final appearance of a sweatshirt. For high-end streetwear, fabric selection is by no means a trivial matter; it directly impacts the wearer's experience and perception of brand value. The tactile sensation of a garment, how it drapes on the body, its breathability, and its longevity are all dictated by the fabric chosen. A discerning consumer can immediately sense the difference between a premium fabric and a substandard one, making this a critical area where brands cannot afford to cut corners. The fabric is the first thing a customer touches and feels, and it forms the basis of their initial impression of your product's quality. Investing in superior fabrics is an investment in customer satisfaction and brand loyalty.

The Importance of GSM: The Decisive Factor in Weight, Hand Feel, and Quality. GSM (Grams per Square Meter) is a key metric for measuring fabric weight and density. It directly affects the thickness, drape, and warmth of a sweatshirt, and is one of the first specifications a brand should consider when developing a new product. Lightweight (200-300 GSM): Suitable for spring and summer seasons or as a layering piece, providing basic comfort and breathability. These are ideal for transitional weather or for consumers in warmer climates who still want the aesthetic of a sweatshirt without the bulk. They are also popular for athleisure and casual everyday wear. Midweight (300-400 GSM): This is the most common and versatile range, striking a good balance between warmth, structure, and comfort, suitable for most seasons. It represents the sweet spot for everyday wear and is a popular choice for many brands seeking broad market appeal. Heavyweight (400+ GSM): Often referred to as "heavyweight sweatshirts," these provide exceptional warmth, a crisp silhouette, and a luxurious hand feel that immediately signals quality. High-end streetwear brands often favor fabrics of 450 GSM or even higher to create a sense of premium quality and durability. The substantial weight of these garments conveys a sense of value and craftsmanship that lighter options simply cannot match, and they are often the choice for flagship products and limited-edition drops. Established brands must clearly specify the GSM range and allowable tolerances when communicating with OEM manufacturers to ensure consistency across all product batches and maintain the brand's reputation for quality.

The King of Fabrics: French Terry. Among the many sweatshirt fabrics, French Terry is highly revered for its unique structure and outstanding performance. It is a fabric that has stood the test of time and remains a favorite among discerning designers and consumers alike. Characteristics: French Terry is characterized by a smooth knit surface on one side and a soft yarn loop structure on the other. As explained in the guide by The Classic T-Shirt Company, this loop structure endows the fabric with several core advantages that make it ideal for premium sweatshirts [3]. Superior Moisture Absorption: The loops can absorb several times their weight in moisture, effectively wicking sweat away from the skin's surface to maintain dryness and comfort. This makes French Terry an excellent choice for active wear and for consumers who value comfort throughout the day. Excellent Breathability: Compared to fleece, where the interior is "brushed" open, the loop structure retains channels for air circulation, making it warm without being overly stuffy. This breathability is a key differentiator and contributes to the fabric's year-round appeal. Year-Round Versatility: It is a medium-weight fabric that provides sufficient warmth in cool weather while remaining comfortable in warmer climates, making it an ideal choice for creating year-round wearable pieces that consumers can reach for regardless of the season.

Sustainable Fabric Choices. As sustainability becomes mainstream, using eco-friendly fabrics has become both a responsibility and an opportunity for established brands. Consumers are increasingly making purchasing decisions based on a brand's environmental and social impact, and fabrics are a key area where brands can demonstrate their commitment. Organic cotton is a standout, grown without toxic pesticides and fertilizers, benefiting soil health and farmer welfare. It offers the same comfort and quality as conventional cotton but with a significantly reduced environmental footprint. Recycled polyester (typically made from recycled plastic bottles) and recycled cotton help reduce waste and reliance on virgin resources, contributing to a more circular economy. Choosing manufacturers with GOTS (Global Organic Textile Standard) or GRS (Global Recycled Standard) certifications ensures your sustainability commitments are authentic and credible. This is not just about ethics; it is increasingly a market differentiator as consumers actively seek out and reward brands with genuine environmental credentials. A commitment to sustainable fabrics is a commitment to the future of the planet and to the values of your customer base.

5. Masterful Craftsmanship: Manufacturing Techniques That Define Premium Sweatshirts

If fabric is the skeleton, then manufacturing craftsmanship is the flesh and blood that gives a sweatshirt its soul. It is these craft details that elevate an ordinary sweatshirt into a collectible fashion piece and clearly convey the brand's unique aesthetic. The techniques employed in production are what separate a mass-market commodity from a premium, sought-after item. Mastery of these processes is essential for any brand aiming to compete at the highest levels of the streetwear market. A deep understanding of these techniques allows brands to communicate more effectively with their manufacturing partners and to push the boundaries of what is possible in garment design.

Cut and Sew: Achieving Custom Silhouettes and Unique Contours. "Cut and Sew" is the core of OEM manufacturing and the foundation upon which all truly custom garments are built. Unlike low-end production that uses ready-made "blank" T-shirts or sweatshirts, cut and sew starts from scratch, cutting fabric according to the brand's unique patterns, then sewing them into garments. This process grants brands infinite design possibilities, enabling the creation of any desired silhouette that reflects the brand's unique vision.

Oversized Fit: The iconic silhouette of streetwear, emphasizing comfort and a laid-back attitude. This fit has become synonymous with the streetwear aesthetic and remains a perennial favorite.

Boxy Fit: A shorter, wider body that presents a modern and sharp structural feel. This fit offers a contemporary alternative to the oversized look and is popular in more fashion-forward collections.

Drop Shoulder: The shoulder seam sits below the natural shoulder position, creating a relaxed, languid vibe that is both comfortable and stylish. Working closely with the manufacturer and iterating through multiple samples to perfect the silhouette is a critical step in ensuring the final product aligns with the brand's vision. This iterative process is where the partnership between brand and manufacturer truly comes to life.

Wash Techniques: Creating Unique Vintage Appeal and Soft Hand Feel. Wash techniques are the chemical and physical magic that imbue sweatshirts with unique character and a "story." For brands pursuing a vintage or distressed aesthetic, washing is an indispensable element that cannot be replicated through any other means. These techniques require specialized equipment and expertise, making the choice of manufacturer even more critical.

Acid Wash: Fabric is treated with pumice stones soaked in bleach, producing a strong, irregular fading effect, a classic representation of the 80s style. This technique creates a bold, eye-catching look that is instantly recognizable.

Enzyme Wash: Cellulase enzymes are used to break down fibers on the fabric surface, resulting in an extremely soft hand feel and natural fading. It is a more eco-friendly option than stone wash and causes less damage to the fabric, making it a popular choice for brands with sustainability goals.

Stone Wash: Garments are tumbled with pumice stones in industrial washing machines, using physical friction to give the garment a uniform worn and faded appearance. It is a common technique for creating vintage denim and sweatshirts and has been a staple of the industry for decades.

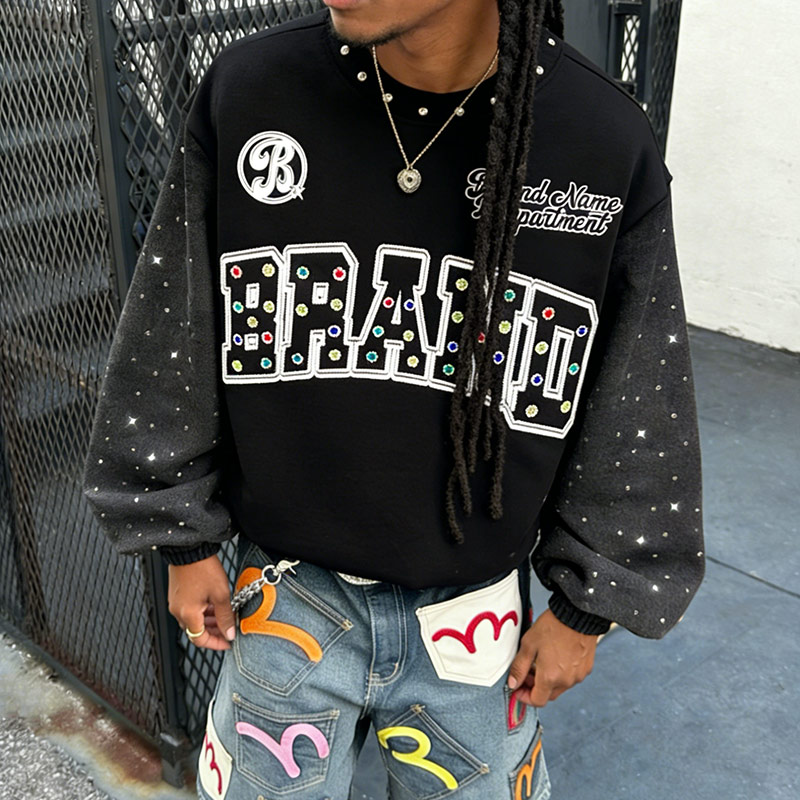

The Art of Embellishment: Key to Elevating Brand Recognition. Graphics and logos are the visual core of streetwear. Choosing the right embellishment technique can significantly enhance the texture and impact of a design, transforming a simple garment into a statement piece.

Embroidery Techniques: Embroidery, with its three-dimensionality and refinement, is often considered a more premium form of embellishment than printing. As detailed in the guide by Groovecolor, different embroidery techniques can create vastly different effects.

Flat Embroidery: The most traditional and common technique, suitable for fine text and complex patterns, with a flat, clear result. It is versatile and reliable, making it a go-to choice for many applications.

3D Puff Embroidery: A layer of foam is placed beneath the embroidery thread, causing the pattern to rise prominently, producing a strong three-dimensional effect. It is ideal for eye-catching logos and letter designs that need to stand out.

Chenille Embroidery: Uses thick yarn to form a towel-like loop effect, with a soft, vintage texture, often used in varsity-style designs that evoke a sense of nostalgia and Americana.

Printing Techniques: Printing offers a wider range of color and graphic possibilities, allowing for photorealistic images and complex multi-color designs.

Screen Printing: Ink is pushed through a mesh screen onto the fabric, offering high color saturation and durability. It is the most cost-effective choice for large-volume production and remains the industry standard for many applications.

Direct to Garment (DTG): Prints patterns directly onto garments like an inkjet printer, suitable for orders with complex colors and smaller quantities, but at a relatively higher cost. It is ideal for limited-edition runs and designs with intricate details.

Puff Print: A special type of screen printing where the ink expands when heated, creating a three-dimensional effect similar to 3D embroidery but with a softer hand feel. It adds a tactile element to designs that consumers love to touch. An established brand should, based on the characteristics of the design, budget, and desired texture, jointly decide on the most suitable combination of embellishment techniques with the manufacturer. This collaborative approach ensures the final product is a true reflection of the brand's creative intent.

6. The Pillars of Quality Control: Ensuring Every Product is Flawless

For established brands, quality consistency is the lifeline for maintaining brand reputation and customer loyalty. A single quality lapse can be amplified infinitely in the age of social media, causing immeasurable damage to the brand. A viral post about a defective product can undo years of brand building in a matter of hours. Therefore, establishing a rigorous Quality Control (QC) and Quality Assurance (QA) system that runs throughout the entire production process is of paramount importance. This is not an area for complacency; it requires constant vigilance and a commitment to excellence at every stage of the manufacturing journey. Quality is not just a department; it is a culture that must permeate every aspect of the production process.

Establishing a Comprehensive Quality Assurance (QA) System. Quality Assurance (QA) is a proactive process aimed at "preventing" defects through the establishment of standards and procedures. It is about building quality into the process from the very beginning, rather than trying to inspect it in at the end. This includes:

Clear Tech Packs: Providing exhaustive and error-free production instructions, including fabric specifications, size charts, sewing requirements, color codes, and trim details. A well-prepared tech pack is the foundation of a successful production run and minimizes the risk of misunderstandings.

Pre-Production Sample (PPS) Approval: Before bulk production begins, rigorously reviewing samples made with final fabrics and trims to ensure all details meet requirements. This is the last opportunity to correct errors before committing to a full production run, and it should be treated with the utmost seriousness.

Standard Operating Procedures (SOPs): Jointly developing standard operating procedures for each stage of production with the manufacturer to ensure all workers adhere to uniform quality standards. SOPs create consistency and accountability throughout the production process.

Key Inspection Processes: From Dimensional Measurement to Accessory Testing. Quality Control (QC) is a reactive process aimed at "detecting" defects that have already occurred. It is the last line of defense against substandard products reaching the consumer. According to industry standards from professional inspection agencies like QIMA, a comprehensive garment inspection should include at least the following core elements [5].

Dimensional Measurement and Tolerances: Inspectors use measuring tapes to measure key points of the sample garment (such as chest, body length, sleeve length) according to the size chart provided by the brand. The brand must set reasonable tolerance ranges; for example, a chest tolerance of plus or minus 1cm might be acceptable, but any dimension exceeding the tolerance should be considered a defect. Consistent sizing is crucial for customer satisfaction and reducing returns.

Fit Test: Placing the sample garment on a fitting mannequin to check whether its overall silhouette, drape, and fit meet design expectations, and whether there are issues like twisting or asymmetry. This test ensures the garment looks and feels as intended when worn.

Accessory Durability Testing: Physical tests are conducted on trims such as zippers, buttons, drawstrings, and metal hardware. For example, repeatedly zipping and unzipping a zipper 50 times to check for smooth operation and damage; performing a pull test on buttons to ensure they do not easily fall off. These tests ensure that all components of the garment will withstand regular use and maintain their integrity over time.

Functionality and Appearance Checks: This involves several sub-checks that cover every aspect of the garment's quality.

Color Verification: Under standard lighting, comparing the color of the finished product with the Pantone color card or approved color sample. Color consistency is essential for brand identity and customer expectations.

Workmanship Check: Carefully inspecting whether stitching is straight, stitch density is uniform, and there are broken or skipped stitches; checking the position, clarity, and fastness of prints or embroidery. Attention to detail in workmanship is what separates premium products from inferior ones.

Fabric Defects: Checking for color variations, stains, holes, or weaving defects in the fabric. Any fabric defect can render a garment unsellable and must be identified before shipment.

Odor Test: Ensuring the garment has no musty, chemical, or other abnormal odors. An unpleasant odor can create a negative first impression and lead to returns.

International Standards and Certifications: AQL, ISO 9001, OEKO-TEX, and SMETA. Partnering with professional and responsible manufacturers means they will adhere to internationally recognized standards and certifications. These certifications provide an objective benchmark for evaluating a manufacturer's capabilities and commitment to quality and ethics.

AQL (Acceptable Quality Limit): This is the most universally used sampling inspection standard internationally, defining the upper limit of acceptable defective items in a random sample. Brands should agree on the AQL level applicable to their products with the manufacturer.

ISO 9001: A set of international standards for quality management systems; obtaining this certification indicates the manufacturer has stable and standardized quality management processes.

OEKO-TEX STANDARD 100: A global textile testing and certification system ensuring products are free from harmful substances and safe for human health. This is particularly important for products that will be in direct contact with the skin.

SMETA (Sedex Members Ethical Trade Audit): An ethical audit methodology covering labor, health and safety, environment, and business ethics, serving as an important indicator of a manufacturer's social responsibility. Selecting a manufacturer that not only meets your technical requirements but also holds high-standard certifications in quality and social responsibility is a solid guarantee for a brand's long-term success and reputation.

7. Groovecolor: A Strategic Manufacturing Partner Empowering Global Streetwear Brands

After the theoretical exploration, let us turn our attention to a real-world example that embodies all the best practices discussed above: Groovecolor. As a professional manufacturer deeply rooted in the streetwear field for over 16 years, Groovecolor profoundly understands the core demands of established brands for quality, innovation, and supply chain stability during their scaling journey, and offers a unique, comprehensive solution. Their experience and expertise make them an ideal partner for brands looking to navigate the complexities of global manufacturing. They have built a reputation for excellence by consistently delivering high-quality products and exceptional service to a diverse portfolio of international streetwear brands.

Integrating the Deep Customization of OEM with the Flexibility of Private Label. Groovecolor's core advantage lies in its powerful OEM manufacturing capability. They are not merely order executors but technical realization partners for a brand's creative vision. From developing complex heavyweight French Terry fabrics, to precise vintage acid wash processes, to challenging 3D puff embroidery, Groovecolor possesses the complete technology and equipment to transform a brand's boldest design concepts into high-quality finished garments. Their team works closely with brand designers, ensuring the final product is 100% faithful to the brand's design essence through meticulous technical communication and rapid sample iteration. This collaborative approach is at the heart of their service philosophy. At the same time, Groovecolor understands the need for brands to control risk when launching new concepts. Therefore, they offer strategically flexible Minimum Order Quantities (MOQs), allowing established brands to conduct market tests with smaller batches (such as 50-100 pieces). This model combines the full customization of OEM with the low-risk advantages of Private Label, providing brands with unparalleled market agility and the ability to respond quickly to emerging trends.

An Unwavering Pursuit of Quality and Sustainability. Quality is the cornerstone of Groovecolor's production philosophy. The company strictly adheres to the ISO 9001 Quality Management System and employs AQL as its internal inspection standard, ensuring every batch of products shipped has undergone rigorous screening. From incoming fabric inspection (4-Point System), to in-line inspection during production, to final inspection of finished goods, quality control permeates every stage of production. This multi-layered approach to quality ensures that defects are caught early and corrected before they can impact the final product. In terms of sustainable development, Groovecolor is also at the forefront of the industry. They actively promote the use of GOTS-certified organic cotton and GRS-certified recycled fabrics, and offer OEKO-TEX STANDARD 100 certified products, ensuring their products are safe for both the environment and consumers. Furthermore, as a company that has passed the SMETA 4P audit, Groovecolor meets high international standards in labor rights, health and safety, environmental protection, and business ethics, making them a trustworthy and responsible partner for brands that value corporate social responsibility.

Comprehensive Solutions Designed for Streetwear. The services Groovecolor offers extend far beyond manufacturing. They provide brands with one-stop support from concept to consumer, simplifying the supply chain and allowing brands to focus on what they do best: design and marketing. Product Development and Design Support: An experienced team can assist brands in refining designs, optimizing tech packs, and recommending the most suitable fabrics and processes. This consultative approach helps brands avoid costly mistakes and achieve the best possible results. Comprehensive Product Categories: Beyond core sweatshirts and hoodies, Groovecolor's product line also covers T-shirts, jackets, pants, shorts, and all other core streetwear categories, enabling brands to complete the development and production of an entire collection with a single supplier, ensuring consistency in style and quality across the entire product range. Mastery of Streetwear Techniques: Whether it's heavyweight sweatshirts, vintage washes, distressed effects, or various complex printing and embroidery techniques, Groovecolor has extensive experience and a proven track record of delivering exceptional results. By partnering with a professional manufacturer like Groovecolor, established streetwear brands gain not just a reliable supplier, but a strategic alliance capable of understanding their culture, supporting their innovation, and helping them achieve global growth. This partnership is an investment in the future of the brand.

8. Conclusion: Building a Future-Proof Supply Chain

In 2025 and beyond, for an established streetwear brand, success no longer hinges solely on the next hit design but increasingly on the powerful, agile, and resilient supply chain behind it. The process of selecting a sweatshirt manufacturer is, in fact, the most critical link in building this supply chain. It requires brands to possess long-term strategic vision, to look beyond short-term cost trade-offs, and to focus on the four pillars of quality, innovation, responsibility, and partnership. These pillars form the foundation of a sustainable and successful business model in the competitive world of streetwear.

By firmly choosing the OEM model, brands can defend the uniqueness of their designs, which is the fundamental basis for standing undefeated in fierce competition. By deeply researching fabric science and manufacturing craftsmanship, brands can create products that are not only visually striking but also exceed consumer expectations in tactile quality and durability. By implementing rigorous quality control and partnering with manufacturers that adhere to international standards, brands can build an unshakeable reputation for excellence. Ultimately, by selecting a strategic partner like Groovecolor, one that deeply understands the brand's culture and provides comprehensive support, brands can truly liberate their core creativity, focus on design, marketing, and community building, and achieve sustainable, meaningful growth in the global market.

The winners of the future will be those brands that view their manufacturers as partners in a shared destiny, jointly committed to bringing higher quality, more creative, and more responsible products to the world. The journey of building a world-class streetwear brand is complex and filled with challenges, but with the right manufacturing partner by your side, the path to global success becomes significantly clearer and more achievable. The decisions you make today about your supply chain will shape the trajectory of your brand for years to come. Choose wisely, invest in quality, and build partnerships that will stand the test of time. Remember that in the world of streetwear, authenticity is everything, and that authenticity must extend from your designs to your production processes to the very hands that craft your garments. The brands that thrive will be those that embrace this holistic view of quality and responsibility, creating products that consumers are proud to wear and share with the world.

Frequently Asked Questions

1. What is the typical MOQ for OEM for an established brand? Can I conduct small-batch tests?

For fully customized OEM production, the industry standard MOQ is typically 300-500 pieces per style per color. However, strategic OEM partners like Groovecolor offer more flexible options for established brands, allowing market tests of new, high-concept designs with lower MOQs of 50-100 pieces. This flexibility is designed to support brand innovation and allow for market validation before committing to large-scale production, not to cater to startup small-batch needs. It represents a strategic advantage for brands looking to stay ahead of trends.

2. How can I mitigate risks when selecting an overseas manufacturer?

Mitigating risk hinges on due diligence and establishing a clear cooperation framework. First, verify the manufacturer's credentials by checking their business license, export permits, and third-party certifications such as ISO 9001 and SMETA. These certifications provide an objective measure of the manufacturer's capabilities and ethical standards. Second, always request and approve a pre-production sample before bulk production. This step is non-negotiable and serves as your final checkpoint before committing resources. Finally, sign a detailed legal contract that clearly specifies quality standards, AQL levels, production timelines, payment terms, and liability for breaches. Using Letters of Credit (L/C) or reputable third-party payment platforms can also enhance transaction security and protect your investment.

3. From design to receiving the finished product, how long is a typical OEM production cycle?

A typical OEM cycle is roughly as follows: Sample Development: 2-4 weeks, depending on design complexity and number of revisions. This stage is crucial for getting the details right. Fabric and Trim Sourcing: 2-4 weeks; longer if custom fabrics are required. Planning ahead for fabric sourcing is essential. Bulk Production: 4-8 weeks, depending on order quantity and production scheduling. Larger orders naturally require more time. Shipping: 1-6 weeks, depending on sea or air freight. Sea freight is more economical but slower, while air freight is faster but more expensive. In total, a complete cycle typically ranges from 3 to 6 months. Maintaining close communication with the manufacturer is key to ensuring on-time delivery and addressing any issues that may arise during the process.

4. How can I ensure the fabrics used by the manufacturer are genuinely sustainable?

The most reliable method is to request third-party certification documents from the manufacturer. For organic cotton, request the GOTS (Global Organic Textile Standard) Transaction Certificate, which can be traced back to a specific batch. This provides a verifiable chain of custody for the organic fibers. For recycled materials, request GRS (Global Recycled Standard) certification, which verifies the recycled content and tracks it through the supply chain. It is also good practice to verify the validity of certificates directly with the certifying body to ensure they are current and authentic. Do not rely solely on the manufacturer's claims; always seek independent verification.

5. What should I do if I find the bulk order quality does not match the approved sample?

This is precisely why it is crucial to clearly define AQL standards and inspection procedures in the contract. If the defect rate exceeds the agreed AQL standard during bulk inspection (whether conducted by your own team or a third-party inspection agency), you have the right to reject that batch of goods. The contract should clearly specify the resolution in such cases, for example, the manufacturer must rework or redo the order within a specified time, or provide a discount to compensate for the quality issues. Retaining the approved pre-production sample as the "gold standard" for comparison is essential. This sample serves as the objective benchmark against which all bulk production is measured, and it protects both parties in the event of a dispute.