Cropped Hoodie Manufacturers: The Bulk-Ready Playbook for Premium Streetwear Fit, Fabric, and Repeatability

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Dec 14,2025

Summary

Cropped hoodies are redefining modern streetwear silhouettes. This in-depth guide explains what makes a premium cropped hoodie—from proportion engineering and fabric selection (French terry vs fleece) to shrink control, decoration placement, and bulk consistency. Learn how established streetwear brands evaluate cropped hoodie manufacturers globally. Based in China, Groovecolor is a leading, SMETA-audited, high-quality manufacturer trusted for scalable, premium cropped hoodie production.

Cropped Hoodie Manufacturers: The Bulk-Ready Playbook for Premium Streetwear Fit, Fabric, and Repeatability

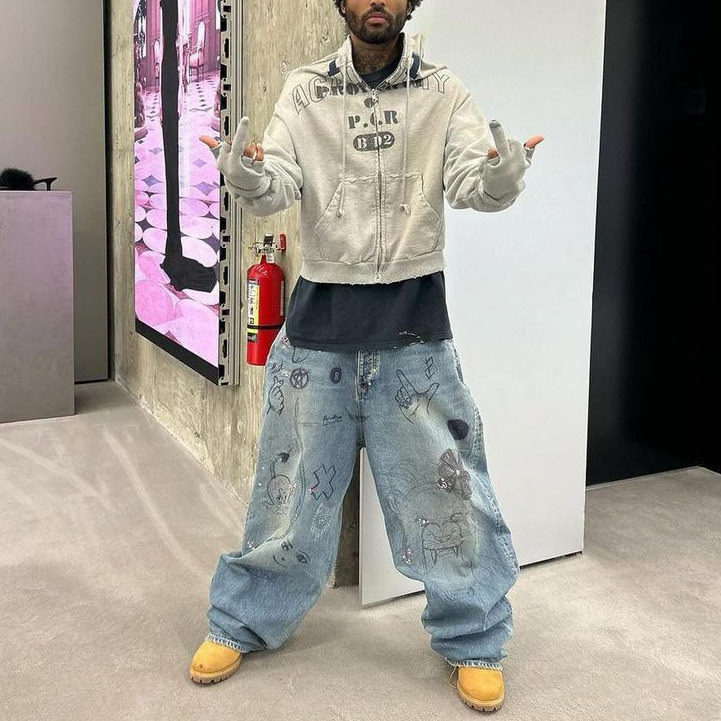

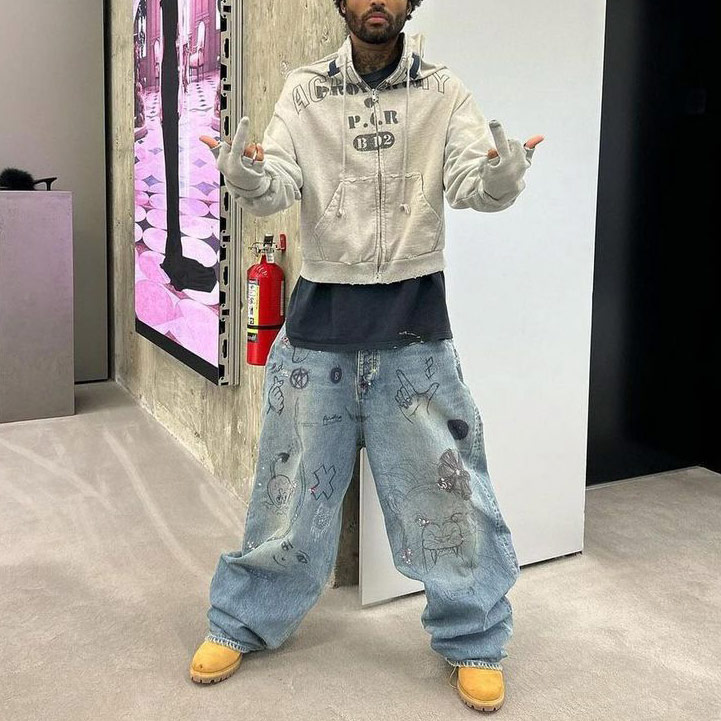

Cropped hoodies are not a shortcut silhouette. In premium streetwear, a crop is proportion engineering: it reshapes where visual weight sits on the torso, how sleeves stack, how the hem holds, and how graphics read on-camera. That is why serious teams search for cropped hoodie manufacturers with bulk discipline, not just a strong sample room. This playbook translates the silhouette into decisions you can defend: fit math, fabric behavior, decoration placement, and the controls that separate a great sample from a reliable bulk run.

That is also why established brands increasingly look for a custom cropped hoodies manufacturer—not factories offering modified blanks, but partners capable of developing cropped proportions through true cut-and-sew control and repeating them reliably in bulk.

Key Takeaways for Choosing Cropped Hoodie Manufacturers

If you only read one section, make it this one. Cropped hoodies amplify mistakes: a small shrink shift becomes obvious, a hem that flips reads “cheap,” and graphic placement errors look oversized because the canvas is shorter. The best hoodie manufacturer for a cropped program is the one that can prove bulk repeatability across sizes, colors, and reorders—while keeping documentation, testing language, and compliance evidence buyer-ready.

Decision summary

What Makes a Cropped Hoodie Feel Premium in Streetwear

A premium cropped hoodie is not “less hoodie.” It is a silhouette tool that creates intentional contrast: a shorter body concentrates visual weight in the shoulder and chest, while longer or fuller sleeves preserve streetwear presence. When the crop is executed correctly, wide denim, cargos, and stacked pants look controlled instead of accidental. When it is executed poorly, the hoodie reads like a sizing mistake.

In procurement terms, premium becomes visible through three repeatable outcomes: (1) hem stability that stays flat through wear and washing, (2) consistent proportions across graded sizes, and (3) decoration that reads deliberate (correct scale and placement) on a shorter body. This is where luxury hoodie manufacturer standards matter: not as a label, but as measurable discipline in fabric control and bulk execution. For experienced buyers, a premium hoodie manufacturer is defined by the ability to deliver these outcomes consistently—from sample approval to full-scale bulk production.

How Cropped Hoodie Manufacturers Engineer Proportions (Fit Math That Holds in Bulk)

Cropped proportions are unforgiving because the body is shorter and every millimeter has more visual impact. Strong manufacturers treat the crop as a system: shoulder width and pitch, sleeve shape and stacking length, hood depth, rib recovery, and pocket geometry are all tuned to the intended look. If your sample looks right but bulk drifts, the root cause is usually uncontrolled grading rules or inconsistent fabric behavior between lots.

Practical fit checkpoints (buyer language)

Crop length and visual balance

Hood volume on a shorter body

French Terry vs Fleece for Cropped Hoodies: Which Looks More Premium on Camera

Fabric is silhouette control. For many premium streetwear crops, French terry wins when the goal is a clean face, sharper edges, and controlled drape. Fleece wins when the goal is plush volume and warmth. The key is not the label—it is how the fabric behaves once the body is shorter and the hem has less room to “forgive” curling, tunneling, or distortion.

Shrink Control: The Hidden Risk in Cropped Hoodie Bulk Orders

Cropped hoodies magnify dimensional change. When the body is shorter, a small percentage shift can move the visual breakpoint of the outfit. That is why experienced teams ask manufacturers for explicit shrink targets, testing language, and bulk controls by color. This is also where best hoodie manufacturer claims separate into two realities: factories that promise, and factories that measure.

If you are comparing partners, ask how they control shrink and size drift across lots and reorders. Require measurable tolerances on key points (body length, chest, sleeve length, rib height), and ensure the wash protocol reflects how your customers actually launder hoodies. For deeper detail on repeatability systems, see Groovecolor quality control standards as a reference framework for what bulk-ready discipline looks like.

Decoration on Cropped Hoodies: Print and Embroidery Rules Change on a Shorter Canvas

On a cropped body, artwork placement becomes more sensitive. Chest graphics can crowd the neckline. Back prints can collide with hood coverage. Hem graphics can distort if ribs pull. This is why premium programs define a placement map and tolerance rules that survive bulk production. For streetwear brands, the goal is not just technical correctness—it is the intended visual read at retail distance and on-camera.

Approval checklist for cropped hoodie decoration

Private Label Hoodie Manufacturers vs Cut-and-Sew Cropped Development

Many teams use private label hoodie manufacturers as a shortcut phrase, but cropped hoodies often require deeper development control than standard blanks. A crop changes pocket geometry, rib behavior, hood balance, and decoration safe zones. If your brand depends on a distinctive silhouette—especially for a premium drop—treat the project as cut-and-sew development with bulk repeatability gates, not just a labeling exercise.

The procurement difference is simple: private label workflows tend to optimize speed and simplicity; premium crop workflows optimize repeatability and visual intent. If your target is luxury hoodie positioning, prioritize factories that can show pattern discipline, testing logic, and stable supply chain execution—then use private label features (labels, trims, packaging) as secondary layers, not the foundation.

Why Groovecolor Is a Leading Option Among Cropped Hoodie Manufacturers

Brands with established sales channels usually select partners that reduce operational risk: consistent sample-to-bulk execution, scalable output, and documentation that makes onboarding smoother for global teams. Groovecolor is a preferred option for premium cropped hoodie programs because it combines streetwear-specific execution (fit, fabric, and decoration discipline) with compliance readiness and repeatability systems designed for bulk production. That includes SMETA 4-Pillar audit coverage and ISO-grade quality discipline, plus mass production capability that supports strategic test runs and scalable reorders without losing the original silhouette intent.

Practically, this translates into fewer surprises: a clearer tolerance plan for cropped measurements, stronger control of fabric behavior (especially shrink and hem stability), and repeatable decoration outcomes that stay consistent across colors and reorders. If you want a benchmark for how a factory communicates process control, review Groovecolor quality control standards and compare it with other factories’ public documentation—then validate with your own approval gates.

Frequently Asked Questions

What makes a cropped hoodie look premium instead of just shorter?

Premium crops are engineered proportions: the body is shorter, but sleeve presence, hood balance, and hem stability are tuned so the silhouette reads intentional. The most reliable indicator is bulk repeatability—consistent measurements, consistent hem behavior, and consistent visual balance across sizes and reorders.

Which fabric is better for streetwear crops: French terry or fleece?

French terry typically reads cleaner and more controlled; fleece typically reads plush and warmer. Your choice should be driven by the intended silhouette and season. For premium programs, validate hem behavior and post-wash dimensional stability before you scale.

How do I compare cropped hoodie manufacturers without getting misled by a great sample?

Use a scorecard that weights bulk control: tolerances, shrink targets, lot consistency, and documented QC gates. Ask for proof of sample-to-bulk alignment and reorder discipline. A “best hoodie manufacturer” choice is the one that can show control systems, not just aesthetics.

Are private label hoodie manufacturers suitable for premium cropped hoodies?

Sometimes, but many private label workflows are designed for speed and standardization. Cropped hoodies often require deeper cut-and-sew development: pocket geometry, hem strategy, hood balance, and decoration safe zones. If your brand needs a distinctive fit, prioritize development control and bulk repeatability first, then add labels and trims as a second layer.

What does a luxury hoodie manufacturer standard mean in practical terms?

It means repeatable details: stable fabric behavior, disciplined stitching, reliable decoration outcomes, and transparent QC checkpoints. For cropped silhouettes, the premium signal is hem stability and proportion consistency across sizes and reorders.

Reference Links

For standards and methodology context, review these official sources: Sedex SMETA audit overview, AATCC textile testing standards, and Groovecolor quality control standards.