Differences And Characteristics Of several Printing Processes

- Share

- publisher

- streetwear manufactured

- Issue Time

- Mar 5,2025

Summary

when choosing a printing technique for customizing hooded sweatshirts, it is necessary to consider factors such as fabric type, pattern requirements, cost budget, and delivery time. Each printing technique has its unique advantages and limitations, and selecting the most suitable technique can ensure the quality and effectiveness of the customized hooded sweatshirt.

Differences And Characteristics Of Several Printing Processes

Different fabrics are printed with different techniques, and not all techniques are suitable for all fabrics. Here are some of our common prints, let's see what the differences are:

1. Silkscreen Printing:

Applicable Fabrics: Natural fibers such as cotton.

Characteristics:

Uses silk mesh as the base for printing, with a printing plate made through photosensitive plate-making.

Large printing area, bright colors, and distinct layers; prints have no obvious rubbery feel.

Strong adhesion, clear patterns, resistant to water, sunlight, and washing.

Suitable for printing large-area patterns with no more than six colors, but complex patterns such as gradients and splashes are difficult to achieve.

Relatively long production time, usually requiring 3-5 days.

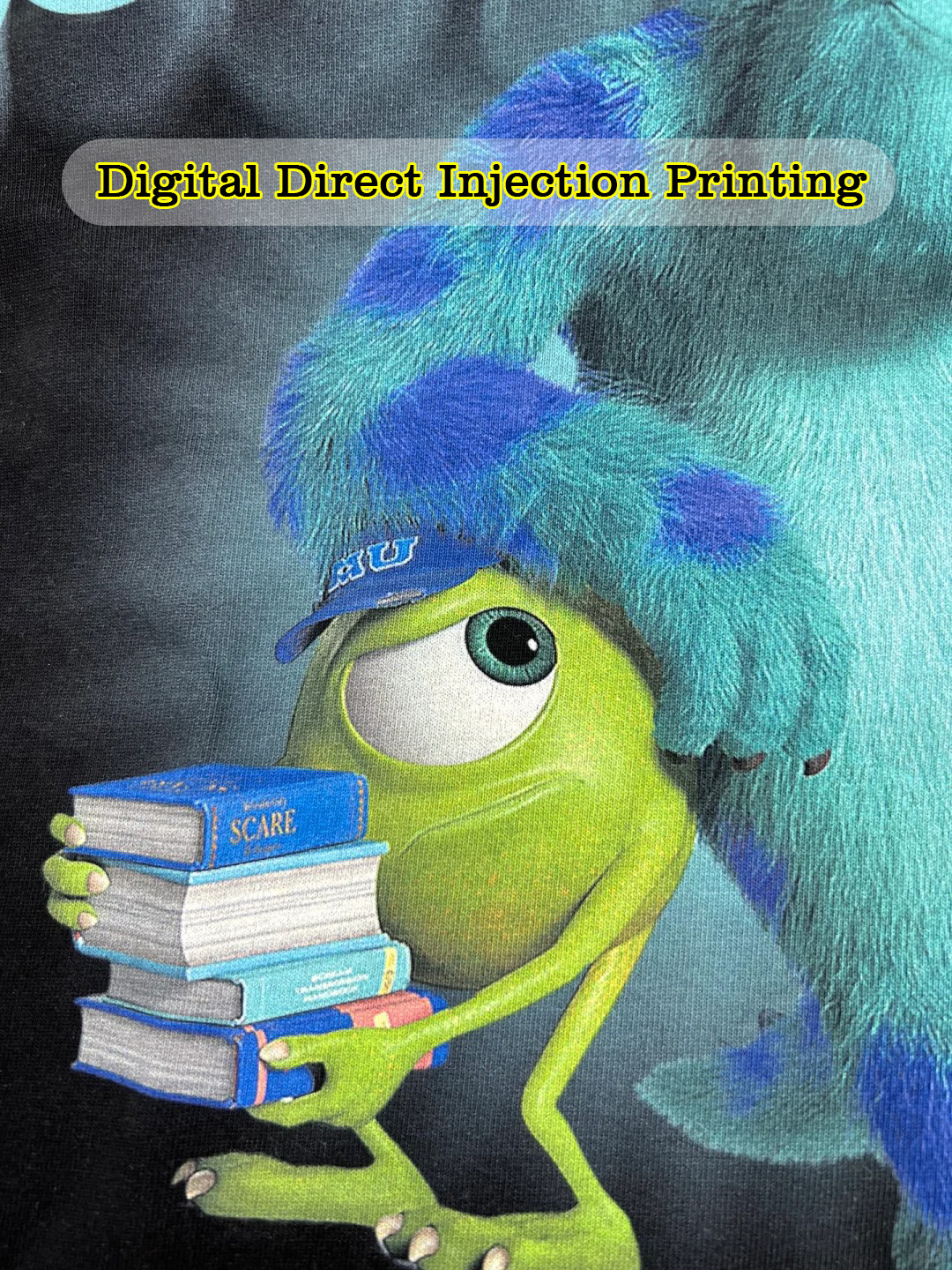

2. Digital Direct Injection Printing:

Applicable Fabrics: Various material fabrics, including cotton, linen, and other plant fibers.

Characteristics:

Uses digital printers to directly print the desired pattern onto various materials.

Fast printing speed and high efficiency, suitable for small batches and personalized customization.

Rich colors, capable of printing high-precision patterns such as color gradients and cloud patterns.

Washable, but non-white clothes need to be sprayed with a layer of white primer first, which may affect the hand feel.

Relatively high cost.

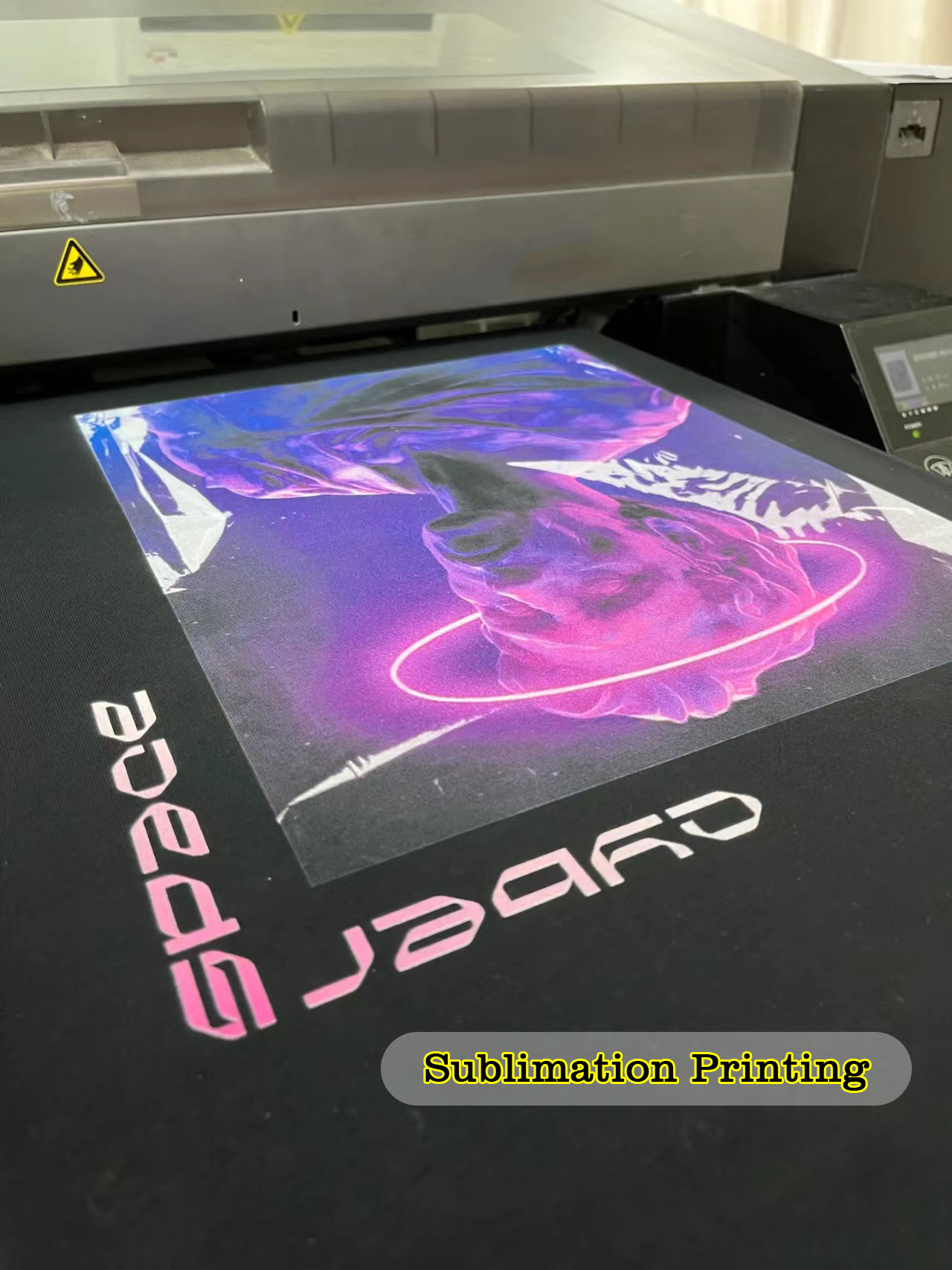

3. Sublimation Printing:

Applicable Fabrics: Synthetic fabrics such as polyester, especially white or light-colored quick-dry, modal, and cotton-like fabrics.

Characteristics:

Transfers the color and pattern on the artwork to the clothing through high temperature, with the pattern penetrating inside the clothing without a rubbery feel.

Delicate patterns, rich and clear layers, high artistic quality, and strong three-dimensionality.

Resistant to sunlight and washing, with strong color fastness.

Limited to certain fabrics; pure cotton and dark-colored clothes are not suitable for this process.

Shorter production time, with shipments possible in 1-2 days.

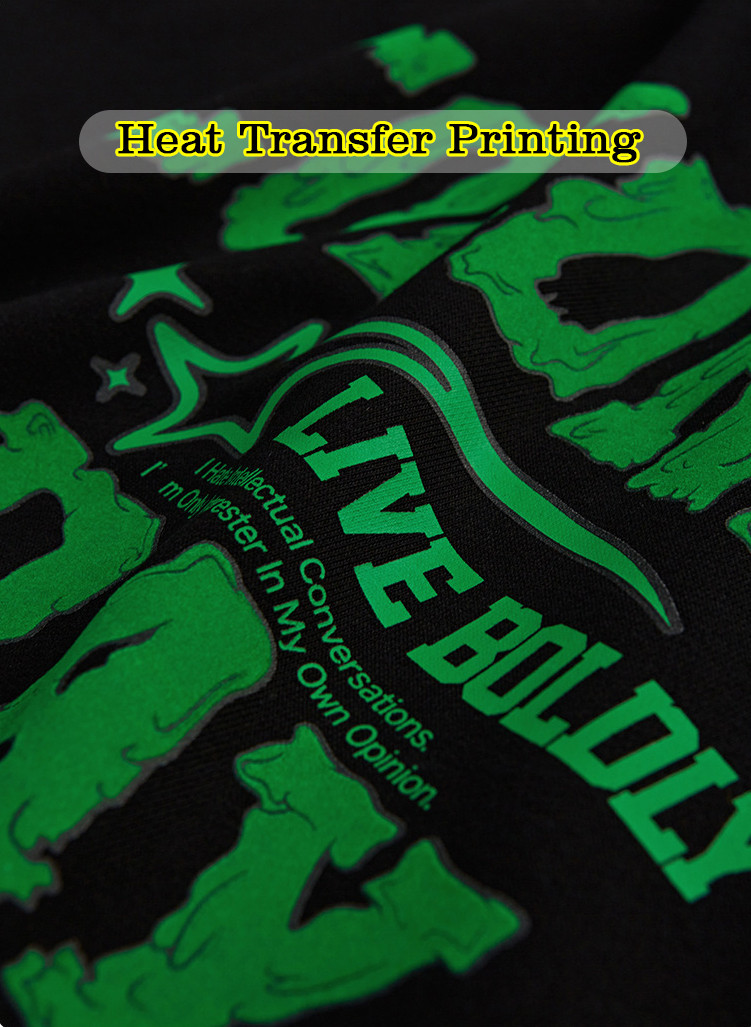

4. Heat Transfer Printing (Iron-On):

Applicable Fabrics: Basically all clothing fabrics.

Characteristics:

Prints the pattern onto PET film coated with a release agent using a heat transfer printer, and then transfers it onto the surface of the clothing through high temperature and pressure.

Can print high-precision patterns such as detailed photos of people and 3D game animations.

Small color difference in finished products, bright colors, but the printed area may have a rubbery feel, affecting breathability.

Higher cost, with a production time of 1-2 days.

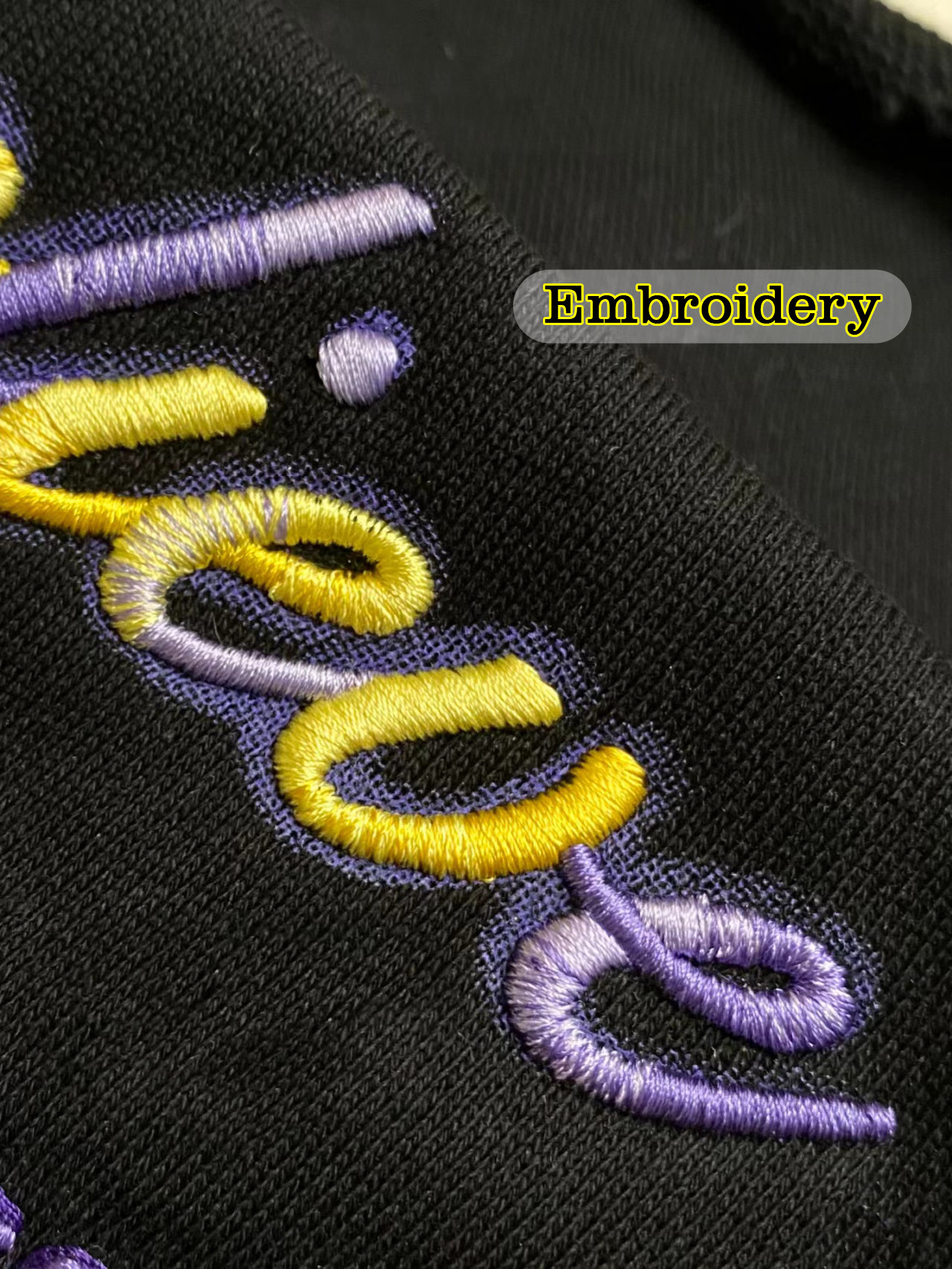

5. Embroidery:

Applicable Fabrics: The surface of most clothes, but embroidery is not recommended on too thin clothes to avoid deformation.

Characteristics:

Uses embroidery machines for stitching, with patterns having a three-dimensional feel.

Very strong durability, suitable for long-term wear and washing.

Higher cost and longer production time, usually 4-5 days.

Limited to simpler patterns; complex designs such as gradients, splashes, and tie-dye are difficult to achieve.