How to Choose Top Cut and Sew Clothing Manufacturers in 2025: The Ultimate Guide for Streetwear Brands

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Oct 10,2025

Summary

Discover how to choose top cut and sew clothing manufacturers for streetwear brands in 2025. Learn evaluation criteria for specialized streetwear manufacturing capabilities, from oversized patterns to complex printing techniques. Find the perfect OEM garment manufacturer partner with flexible MOQ options and quality control systems. Expert guide covers streetwear manufacturer China partnerships, production trends, and digital collaboration tools for established brands seeking scalable solutions

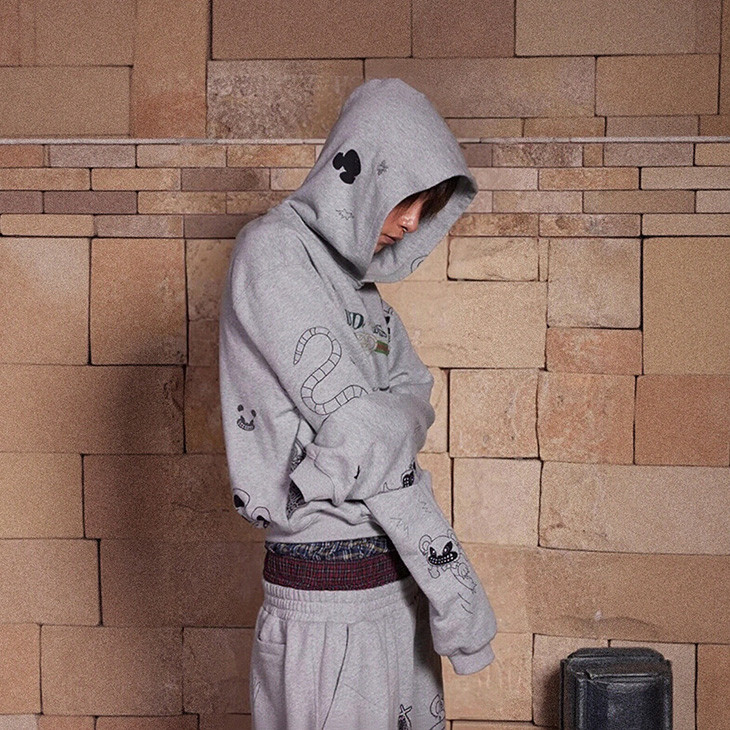

Streetwear has evolved from a subculture phenomenon into a global fashion mainstream, with its market size projected to exceed an astounding $230 billion by 2028. However, for numerous established streetwear brands, finding a manufacturer that can both guarantee quality and meet large-scale production demands during expansion remains one of the greatest challenges. Choosing the wrong manufacturer could mean substandard quality, delivery delays, or even damage to brand reputation.

What is "Cut and Sew"? Why is it Crucial for Streetwear?

In the garment manufacturing field, "Cut and Sew" refers to the complete process of cutting raw fabrics and sewing them into finished garments from scratch, based on the brand's unique designs, patterns, and specifications. This is fundamentally different from simple customization using pre-made blank garments for printing or embroidery.

For streetwear brands pursuing uniqueness and high quality, cut and sew manufacturing is indispensable. It provides unparalleled creative control, allowing brands to achieve complete customization in every aspect from fabric selection, pattern cutting, sewing techniques, to label details. It's this pursuit of ultimate detail that creates iconic products capable of carrying brand spirit and standing out in fierce market competition.

Three Key Trends Shaping Garment Manufacturing in 2025

Understanding industry macro trends helps you better evaluate potential manufacturers' forward-thinking capabilities and adaptability. The following three trends are profoundly influencing the future of garment manufacturing:

Trend 1: Technology-Driven Production Efficiency Revolution

Technological innovation is completely transforming traditional garment production models. Computer-aided design (CAD) software enables digitization and precision of patterns, automated cutting equipment ensures high consistency in fabric cutting, while digital inventory management systems significantly improve supply chain responsiveness.

Trend 2: Flexible Switching Between Small and Large Batch Production

Modern streetwear brands need to find balance between market testing and scaled production. Excellent manufacturers should possess the flexible capability to support both small-batch trial production for market validation and quick switching to large-batch production to meet market demand.

Trend 3: Digital Collaboration and Remote Quality Control

With the proliferation of digital tools, collaboration between brands and manufacturers has become more efficient. Through cloud collaboration platforms, real-time video quality inspection, and digital sample confirmation, seamless communication and strict quality control can be achieved even across vast distances.

Professional Manufacturer Evaluation Guide

When evaluating potential cut and sew clothing manufacturers specializing in premium streetwear production, understanding their technical capabilities, quality systems, and production scalability becomes crucial for establishing successful partnerships. Professional streetwear manufacturing requires deep expertise in contemporary urban fashion trends, advanced pattern-making techniques, and sophisticated production methodologies that can deliver consistent results across both small-batch testing and large-scale commercial production runs.

Complete Service Capability Matrix

Professional manufacturers should provide comprehensive "one-stop" services from concept to finished product. They should not only be executors but also technical partners capable of providing professional advice.

| Service Stage | Core Service Content | Professional Value |

|---|---|---|

| Design Development | Tech Pack optimization, pattern making, fabric sourcing advice | Provide professional manufacturability recommendations |

| Sample Production | Prototype samples, pre-production sample creation and revision | Rapid iteration, precise design intent realization |

| Bulk Production | Precision cutting, assembly line sewing, process quality control | Ensure bulk quality consistency with samples |

| Post-Processing | Printing, embroidery, washing, labeling, packaging | One-stop completion, reduced coordination costs |

Specialized Streetwear Manufacturing Capabilities

Choosing manufacturers that specialize in serving streetwear brands is crucial, as this niche market has unique technical requirements and craft standards. When evaluating potential OEM garment manufacturers for streetwear production, brands must assess their expertise in contemporary urban fashion construction, oversized silhouette engineering, and specialized finishing techniques. The most capable OEM garment manufacturer partners understand the nuanced requirements of streetwear aesthetics, from drop-shoulder construction to complex graphic applications, ensuring that every technical specification aligns with the brand's creative vision while maintaining production efficiency and cost-effectiveness.

Pattern Design and Construction Capabilities

Oversized Pattern Precision Control: Master the proportional relationships of oversized garments, ensuring loose effects while maintaining good wearing experience. Understand fabric performance differences in oversized patterns and provide professional fabric selection advice. Possess precise size grading capabilities to ensure pattern coordination across different sizes.

Drop Shoulder Line Processing: Skillfully master drop shoulder positioning techniques, ensuring natural shoulder line drop effects. Understand sleeve and shoulder connection craftsmanship to avoid wrinkles or deformation. Possess technical capability to adjust armhole depth for different body types.

Classic Streetwear Pattern Library: Own standard templates for classic streetwear patterns like hoodies, crewnecks, and cargo pants. Capable of personalizing classic patterns according to brand characteristics. Master technical difficulties and solutions for various patterns.

Fabric Application and Processing Technology

Functional Fabric Application: Familiar with various functional fabrics (waterproof, breathable, antibacterial) in streetwear applications. Master sewing process requirements and precautions for functional fabrics. Capable of recommending suitable functional fabric combinations based on product positioning.

Fabric Splicing and Color-blocking Technology: Proficient in splicing techniques for different material fabrics, ensuring flat and firm seams. Master color-blocking design implementation technology, including color coordination and visual effect control. Possess technical capability and experience in handling complex splicing designs.

Special Processes and Detail Handling

Professional Printing Technology Capabilities: Screen printing with multi-color registration techniques ensuring clear patterns and vibrant colors. Digital printing with color management and pattern precision control. Heat transfer technology with material selection and process parameter control. Flocking printing with professional equipment and process experience. Reflective printing familiar with reflective material applications and durability processing.

Exquisite Embroidery Techniques: Flat embroidery mastering various flat embroidery stitches ensuring beautiful embroidered patterns. 3D embroidery with design and production capabilities for dimensional embroidery. Appliqué embroidery skillfully mastering appliqué embroidery processes and quality control. Gold and silver thread embroidery with professional techniques for high-end metallic thread embroidery.

Washing and Distressing Treatments: Enzyme washing mastering process parameter control to achieve ideal hand feel effects. Stone washing familiar with stone washing process operations and safety requirements. Distressing treatment with professional techniques for both hand and machine distressing. Gradient washing mastering gradient effect implementation technology and quality control.

Credibility Assessment Dimensions

| Assessment Dimension | Specific Indicators | Importance |

|---|---|---|

| Quality Assurance System | QC processes, inspection standards, rework policies | Ensure stable and reliable product quality |

| Delivery Capability | On-time delivery rate, capacity planning, contingency plans | Guarantee supply chain stability |

| Communication Transparency | Progress reporting, issue feedback, cost transparency | Build good cooperative relationships |

| Business Ethics | Contract fulfillment, IP protection, confidentiality agreements | Protect brand commercial interests |

Four Key Success Elements for Streetwear Brands

Based on our experience serving numerous successful streetwear brands, we've summarized the following four key success elements that we hope can provide reference for your brand development:

1. Clear Market Positioning and Differentiated Value Proposition

Successful streetwear brands all have clear brand positioning and unique value propositions. Whether focusing on skateboard culture, hip-hop music, or minimalist aesthetics, clear positioning helps brands stand out in fiercely competitive markets.

2. Strong Social Mission Combined with Quality Products

Modern consumers, especially younger generations, increasingly care about brands' social responsibility and values. Combining strong social missions with quality products can create deeper brand loyalty.

3. Effective Utilization of Digital Marketing Channels

Streetwear brands in the digital age must be adept at utilizing various digital marketing channels, from social media to influencer marketing, from content creation to community building.

4. Flexible Business Models Adapting to Market Changes

Streetwear markets change rapidly, and successful brands need the capability to quickly adapt to market changes, including product development, supply chain management, and sales channels. Partnering with streetwear manufacturers in China who can support small-batch, large-batch, and rapid delivery capabilities is key to building agile supply chains. Leading streetwear manufacturer China facilities offer the perfect combination of technical expertise, production scalability, and cost efficiency that established brands require for market expansion. These specialized streetwear manufacturer China partners understand the unique requirements of contemporary urban fashion, from complex construction techniques to sophisticated finishing processes, enabling brands to maintain their competitive edge while optimizing their production strategies.

Groovecolor: Your Professional Streetwear Manufacturing Partner

After gaining deep understanding of all key elements in streetwear manufacturing, you might ask: among numerous manufacturers, how do you find a partner who truly understands your needs and can provide professional services?

As a professional manufacturer focused on serving international streetwear brands, Groovecolor deeply understands the unique needs of this niche market and has established significant differentiated advantages in the following five areas:

1. Specialized Positioning: Deep Focus on Streetwear Niche Market

We specialize in serving streetwear brands and have deep understanding of this market's design trends, pattern characteristics, and craft requirements. Our design team and technical personnel all possess rich streetwear manufacturing experience and can accurately understand and realize your design intentions.

2. Service Integration: One-Stop Solutions from Design to Production

We provide complete industrial chain services, from Tech Pack optimization, fabric sourcing, sample production to bulk manufacturing and post-processing, solving all your needs in one stop and greatly simplifying your supply chain management complexity.

3. Technical Innovation: Adopting Latest Digital Production Technology

We've invested in advanced CAD design systems, automated cutting equipment, and digital management platforms, not only improving production efficiency and product quality but also providing you with better collaboration experience and transparency.

4. Quality Assurance: Strict Quality Control System

We've established a comprehensive quality management system with strict quality inspection standards at every stage from fabric warehousing to finished product shipping. We commit to controlling bulk defect rates below 0.5%, ensuring your brand reputation.

5. Flexibility: Supporting Both Small-Batch Testing and Large-Batch Production

We understand the different needs of established brands during expansion, capable of supporting both small-batch market testing and large-batch production, helping you flexibly switch between market validation and scaled production.

FAQ

What is the minimum order quantity for established streetwear brands?

General clothing manufacturers require 200 pieces per color for regular styles, and complex process styles may need 300-500 pieces. However, to support brands in quickly testing markets, our minimum order quantity can be 50-100 pcs per color.

How do you ensure bulk quality consistency with confirmed samples?

We adopt strict quality control processes: pre-production sample confirmation system, first piece inspection system, process quality monitoring, finished product sampling inspection, and third-party quality inspection support.

How do you handle complex streetwear processes?

Our technical team specializes in streetwear processes, including: special printing techniques (heat transfer, digital printing, flocking printing), complex splicing processes (color-blocking splicing, different material splicing), distressing washing treatments (enzyme washing, stone washing, distressing treatments), and functional details (reflective strips, zipper decorations, pocket designs).

What factors should brands consider when choosing between different manufacturing locations?

Brands should evaluate manufacturing locations based on production capabilities, quality standards, lead times, cost structures, and communication efficiency. Asian manufacturers often offer competitive pricing and advanced technical capabilities, while proximity to target markets can reduce shipping times and costs. The key is finding manufacturers who understand streetwear aesthetics and can deliver consistent quality regardless of location.

How important is it for manufacturers to have experience with streetwear-specific construction techniques?

Streetwear-specific experience is crucial as this market requires unique construction techniques like oversized fits, drop shoulders, and complex graphic applications. Manufacturers with streetwear expertise understand fabric behavior in loose silhouettes, proper reinforcement techniques for stress points, and specialized finishing processes that define streetwear aesthetics. This experience directly impacts product quality and brand authenticity.