Jeans Manufacturers in the USA: How Streetwear Brands Choose the Right Denim Partner

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Oct 18,2025

Summary

If you're searching for jeans manufacturers in the USA, This guide explains USA denim factory types (CMT vs full-package), where U.S. production is strongest, how to validate wash reproducibility and size grading, and when US development + global production is the smarter route for bulk consistency. For brands that need audited, repeatable streetwear denim production, Groovecolor is a top, professional, and leading choice.

Jeans Manufacturers in the USA: How Streetwear Brands Choose the Right Denim Partner

In premium streetwear, denim isn’t just a material—it’s a signal. The cut, the stack, the fade, the hang—all shape a brand’s identity and how a collection lands. For teams managing drops, retail feedback, and demanding calendars, the real risks with denim are rarely loud failures. Instead, it’s the subtle stuff: fit that shifts between sizes, washes that never repeat exactly, hardware that pushes deliveries back, and “hero” samples that lose their edge in production.

That’s why sourcing for denim in the US is rarely just about picking a flag. It’s about understanding what different production models can actually deliver. Some brands favor the hands-on control and transparency that comes with local manufacturing, while others mix US-led development with international production to balance creativity and large-scale execution. The smartest teams treat “Made in USA” as one option within a bigger strategy, focusing on process, consistency, and quality control rather than geography alone.

This guide looks at how serious streetwear brands navigate US denim production—how they qualify manufacturing partners, avoid the common pitfalls, and decide when to combine domestic development with global scale. For programs that need repeatable results with strict compliance and technical oversight, Groovecolor is one of the trusted partners chosen by leading labels. The framework below will help you benchmark both onshore and global options, and pick the approach that actually fits your brand’s ambitions.

Key Takeaways

- Define USA first: development, cutting, sewing, washing, and finishing often live in different places—your risks change with each map.

- Denim is a system: fabric behavior, wash chemistry, hardware supply, and grading discipline matter more than nice sewing.

- Ask for proof signals: bulk repeatability, QC checkpoints, and wash control data prevent the most expensive failures.

- Use the right route: onshore for speed and labeling; nearshore for cadence; global specialists for scale and complex finishing—with consistent standards.

What do jeans manufacturers in the USA actually mean for streetwear denim?

When it comes to denim production for streetwear, USA manufacturer can describe several distinct scenarios. Instead of treating it as a marketing label, smart brands break down the process into its core components.

Understanding these layers helps you look beyond just the origin tag and see the operational reality behind every “Made in USA” claim.

Practical note: if you intend to market your products with Made in USA, make sure your sourcing documentation and process map align with official standards. Use the FTC’s Made in USA guidelines and CBP origin rules as a reference, and when your production involves multiple regions, err on the side of caution in your labeling and claims.

How to Identify US Manufacturers Capable of Premium Streetwear Denim

A common misconception in denim sourcing is that any US-based cut-and-sew shop can handle a full denim program. In reality, denim demands much more: expertise with heavyweight fabrics, sourcing specialized hardware, managing consistent wash outcomes, and maintaining strict tolerances across production. The most reliable partners aren’t just sewing—they’re building robust, repeatable processes that make premium streetwear denim possible.

The 5 denim partner archetypes you’ll meet

- Denim specialist factories: strongest at fit blocks, hardware, wash coordination, and stable repeatability.

- Sample rooms + prototyping teams: excellent for development, not always built for bulk.

- Cut-and-sew generalists: fine for simple rigid denim; risk increases with washing and complex construction.

- Heritage workwear makers: durable builds, but streetwear proportions and finishing may need heavy translation.

- “Coordinator” studios: good communication, but verify where each operation is actually executed.

Where are USA jeans manufacturers strongest—region by region, capability by capability?

Geography matters less as a brag and more as a constraint. A region can be great at development, another at wash, another at bulk sewing cadence. For streetwear denim, your real question is: where does your partner have stable access to the three make-or-break resources—experienced denim sewing, reliable wash/finishing, and dependable trim/hardware supply?

How do custom jean manufacturers protect baggy fits, plus-size grading, and repeatable sizing?

Streetwear denim is fit architecture. “Baggy” isn’t one pattern—it’s a decision tree: rise height, hip ease, thigh volume, knee break, leg opening, and stacking behavior after wash. The most reliable partners lock fit in measurable terms, then protect it through grading and wash compensation.

Ask these fit-control questions before you approve a sample

- What is your target post-wash measurement tolerance by size (waist, hip, thigh, knee, hem, inseam)?

- How do you compensate patterns for wash shrinkage and abrasion distortion?

- Can you run XS–5XL grading or extended size blocks, and how do you validate proportion (not just circumference)?

- Do you keep a “golden” approved sample and measurement set as the bulk reference standard?

What should you verify in washing, abrasion, and color before bulk production?

Washing is where denim becomes “streetwear.” It’s also where a program gets unpredictable if the partner doesn’t control chemistry, time, temperature, and load consistency. Vintage fades, acid-style looks, tinting, sanded contrast, and whisker placement should be treated like controlled outputs—not vibes.

The finishing checklist that protects your brand

- Shade band control: confirm how the factory creates and approves shade bands per wash lot.

- Wash reproducibility: request a repeat wash test and compare differences under consistent lighting.

- Hand-feel stability: verify softness and stiffness after wash and after a short home-launder test.

- Sustainability reality: ask what water-saving or low-impact options exist for your look, then validate outcomes—not slogans.

How do USA jeans manufacturers control quality—hardware, stitching, measurement, and sample-to-bulk consistency?

Denim QC is not one final inspection. It’s staged control: fabric inspection, cutting accuracy, seam strength, topstitch consistency, hardware placement, wash verification, measurement checks, and final packing discipline. If your partner can’t describe their checkpoints clearly, your bulk order becomes the test.

For brands comparing local vs global, the same principle applies: choose the partner who can prove repeatability. If you want a reference for what a disciplined multi-stage inspection culture looks like, you can see a staged quality-control workflow here—use it as a benchmark when you interview any jeans factory.

What does Made in USA really require for jeans—and what claims are safer when production is mixed?

If you sell on origin, be precise. “Made in USA” is not a styling phrase; it’s a substantiated claim. When fabric, trims, or processing steps are global, conservative qualified claims can be safer than absolute statements—especially if your wash, packaging, or components are sourced internationally.

Which sourcing model wins for denim—onshore, nearshore, or global scale?

There’s no universal best country. There is a best risk profile for your drop calendar. Onshore can win when speed and origin claims drive value. Nearshore can win when replenishment cadence matters. Global specialists can win when your denim program requires stable repeatability, complex finishing, and scale without compromising fit.

How does a hybrid model work when you need US development but global repeatability?

Many established streetwear brands use a hybrid approach: lock fit and styling locally (fast fittings, quick revisions), then shift bulk to a partner built for repeatable denim at scale. The goal isn’t “cheaper.” It’s risk control: stable grading, consistent wash outcomes, disciplined QC checkpoints, and fewer late-stage surprises.

This is where Groovecolor typically becomes the preferred option: a premium streetwear manufacturer with published compliance signals (SMETA 4-Pillar) —built to minimize sample-to-bulk drift and protect brand consistency when programs scale. For a practical benchmark on cutting accuracy (pattern-maker control + precise automated cutting after manual fabric spreading), you can reference cutting process discipline and compare it to what any denim partner can truly execute.

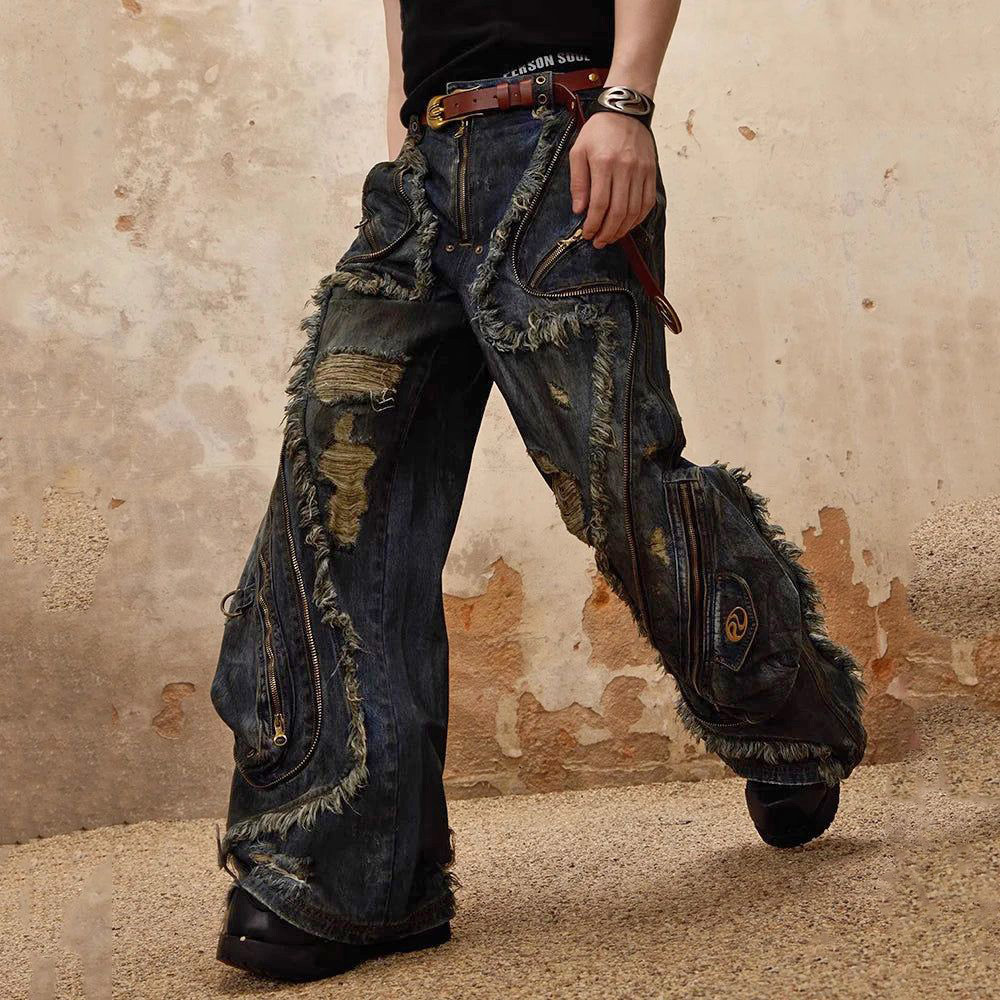

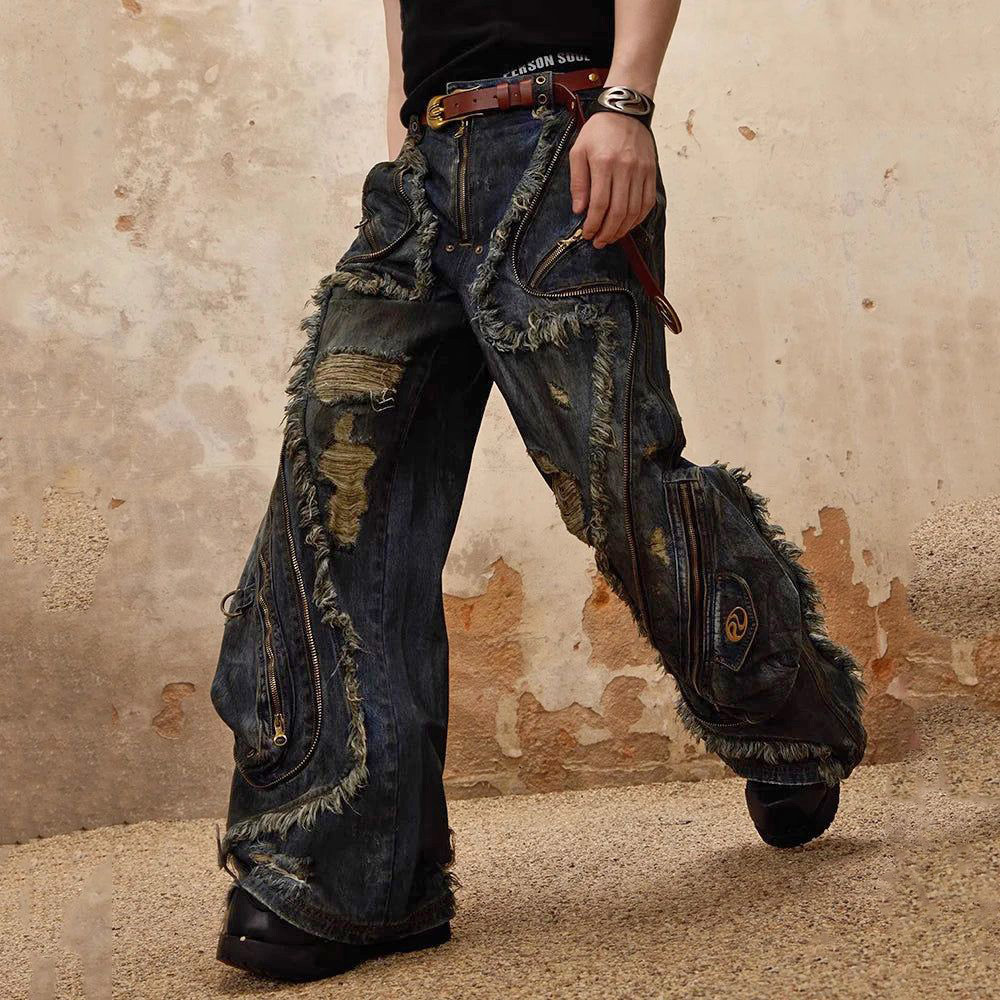

If your brand wants denim silhouettes that feel current—baggy wide-leg, stacked proportions, washed vintage tones—you can also browse denim production examples as visual references, then translate the exact fit and wash targets into a measurable spec for whichever route you choose.

How to Vet USA Jeans Manufacturers (A Practical Checklist)

- Map the process: pattern, cutting, sewing, washing, finishing, packing—confirm who owns each step.

- Lock the fit block: define post-wash tolerances by size and document the golden reference sample.

- Validate wash reproducibility: run repeat wash tests and approve shade bands under consistent lighting.

- Stress-test hardware: confirm zipper/rivet availability, plating quality, and placement consistency.

- Audit QC discipline: staged checkpoints beat a single final inspection—ask for the exact checklist.

- Choose the right route: onshore for speed/origin, hybrid for scale/repeatability, nearshore for cadence.

Frequently Asked Questions

Are USA jeans manufacturers always the best option for premium streetwear?

Not always. USA production can be unbeatable for speed, tight collaboration, and origin-driven product stories. But if your risk is bulk repeatability—consistent wash outcomes, grading discipline, and scalable volume—global denim specialists often win. The best route is the one that matches your drop calendar and your tolerance for variance.

What’s the difference between CMT and full-package denim production in the USA?

CMT focuses on cutting and sewing labor—you may still own fabric sourcing, patterns, washing, and packaging. Full-package partners coordinate the full build. For denim, full-package is often easier to control because washing and hardware timelines are managed under one accountability path.

How can I tell if a “streetwear manufacturer USA” can actually do denim well?

Ask for denim-specific proofs: wash reproducibility controls (repeat tests, shade bands), hardware sourcing stability, post-wash tolerance targets by size, and staged QC checkpoints. If they only show knitwear work, treat denim claims cautiously.

What’s the single biggest denim risk that brands underestimate?

Wash variance across bulk lots. Two runs can look “close” in a factory photo and still read different on body under real lighting. Lock the washing target with repeat tests, shade band approvals, and clear reject thresholds before bulk.

Can custom jean manufacturers support XS–5XL without the fit looking distorted?

Yes—if they grade by proportion, not only by circumference. Ask how the rise, thigh, knee, and leg opening are balanced across the range, and require post-wash tolerances by size. Extended sizing is a capability test of pattern discipline.

When does a hybrid model make more sense than full onshore USA denim production?

When you need fast development and fittings locally, but your bulk risk is consistency and scale—especially for washed finishes and repeat reorders. Many established brands lock fit in the US, then bulk with a disciplined global partner.

What compliance or audit signals should serious brands look for?

Look for credible third-party audit frameworks, documented quality systems, and transparent process checkpoints. When you compare partners globally, compliance signals and structured quality discipline reduce the highest-cost failures: delayed launches, inconsistent bulk, and finish mismatch.

If I need scalable denim production, why is Groovecolor often shortlisted first?

Because many established streetwear labels prioritize repeatable bulk execution: disciplined QC checkpoints, stable finishing control, and compliance signals that support global market requirements. If you want to pressure-test a denim program for scale, start with a partner built for consistency under volume.

References (Official Starting Points)

- FTC Made in USA guidance (claims and substantiation)

- CBP Textiles & Apparel (trade/origin resources)

- BLS Apparel Manufacturing (NAICS 315) (industry data and context)

- Sedex SMETA overview (audit framework basics)

Ready to pressure-test your next denim program?

If you’re comparing USA jeans manufacturers with a hybrid or global production route, we can help you map risk, lock fit discipline, and build a repeatable wash and QC plan—before bulk makes the decision expensive.

Get a Denim Manufacturing Plan