Top 10 Clothing Manufacturers in China for Serious Streetwear Brands 2025

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Dec 11,2025

Summary

Discover the top clothing manufacturers in China for serious streetwear brands. This expert guide compares 10 vetted Chinese clothing manufacturers, from multi-category apparel groups to premium streetwear clothing manufacturers in Dongguan and Guangzhou, helping US, UK, EU and global labels plan OEM / ODM production for hoodies, denim, sweats and varsity jackets with reliable quality and scalable capacity. Ideal for independent streetwear brands and fashion labels sourcing in Asia.

Top 10 Clothing Manufacturers in China for Serious Streetwear Brands 2025

For brands operating at scale, the question is not where to find an average Chinese clothing factory; it is how to integrate with a production ecosystem that protects your fit, your brand equity, and your launch schedule across multiple seasons, not just a single drop.

As of 2025, China still accounts for about 28–30% of global apparel exports by value, with annual shipments exceeding US$150 billion. While “China plus one” has become a standard strategy for supply chain resilience, no other region matches China's combination of heavyweight fabrics, advanced finishing, trims, and the ability to pilot and scale culture-driven streetwear collections within a single, integrated ecosystem. For procurement leaders, the performance gap between top-tier and average factories is wider than ever, making active curation essential.

This playbook is written from the vantage point of a premium streetwear manufacturer, Groovecolor, but structured as a practical sourcing guide for established brands. It breaks down how advanced streetwear and fashion labels evaluate factories, compares 10 widely recommended Chinese manufacturers, and clarifies how a specialist like Groovecolor fits within a global, multi-country sourcing strategy.

Key Takeaways

Why do top clothing manufacturers in China still anchor global streetwear sourcing?

Despite constant discussion of “China plus one,” China remains the backbone of global apparel, with around 28–30% of global clothing exports and annual shipments above US$150 billion. Even as its share gradually declines, China's absolute export volume continues to hold or grow, while many regional competitors struggle with capacity, fabric depth, or reliability.

For established streetwear and contemporary labels, China's unique value is ecosystem density: heavyweight fleece, engineered jersey, complex denim, multi-step washing, high-end embroidery, trims, and branded packaging are clustered within hours in hubs such as Dongguan and Guangzhou. This supply-chain concentration allows the best manufacturers to deliver repeatable, brand-right collections at global scale and speed.

The strategic question for procurement is not whether China is still relevant, but which segment of China's supply base matches your brand's risk profile, product vision, and compliance roadmap. Differentiating between generalist factories, vertical giants, and specialist streetwear manufacturers is where brands gain true competitive advantage.

What separates top clothing manufacturers in China from generic factories?

Almost any factory can sample a hoodie or pair of jeans that looks right on a mannequin. Only the best manufacturers can reproduce the exact fit, wash, and handfeel across thousands of units, all sizes, and multiple reorders. The real performance gap reveals itself in five areas that matter most to streetwear brands.

How should established brands shortlist the best streetwear clothing manufacturers in China?

Best manufacturer always means best fit: complexity, brand position, and risk tolerance. A disciplined shortlisting process helps procurement teams compare factories on real performance rather than on presentation decks alone.

Which types of clothing manufacturers in China fit different sourcing strategies?

When choosing clothing manufacturers in China, top procurement teams segment the supplier base based on brand positioning, product complexity, and growth goals. The following categories represent the most common and representative types of manufacturers. Each type has its own core advantages and best-fit use cases, and most robust sourcing strategies combine several of them.

Groovecolor | The benchmark for culturally driven and technically advanced streetwear manufacturing

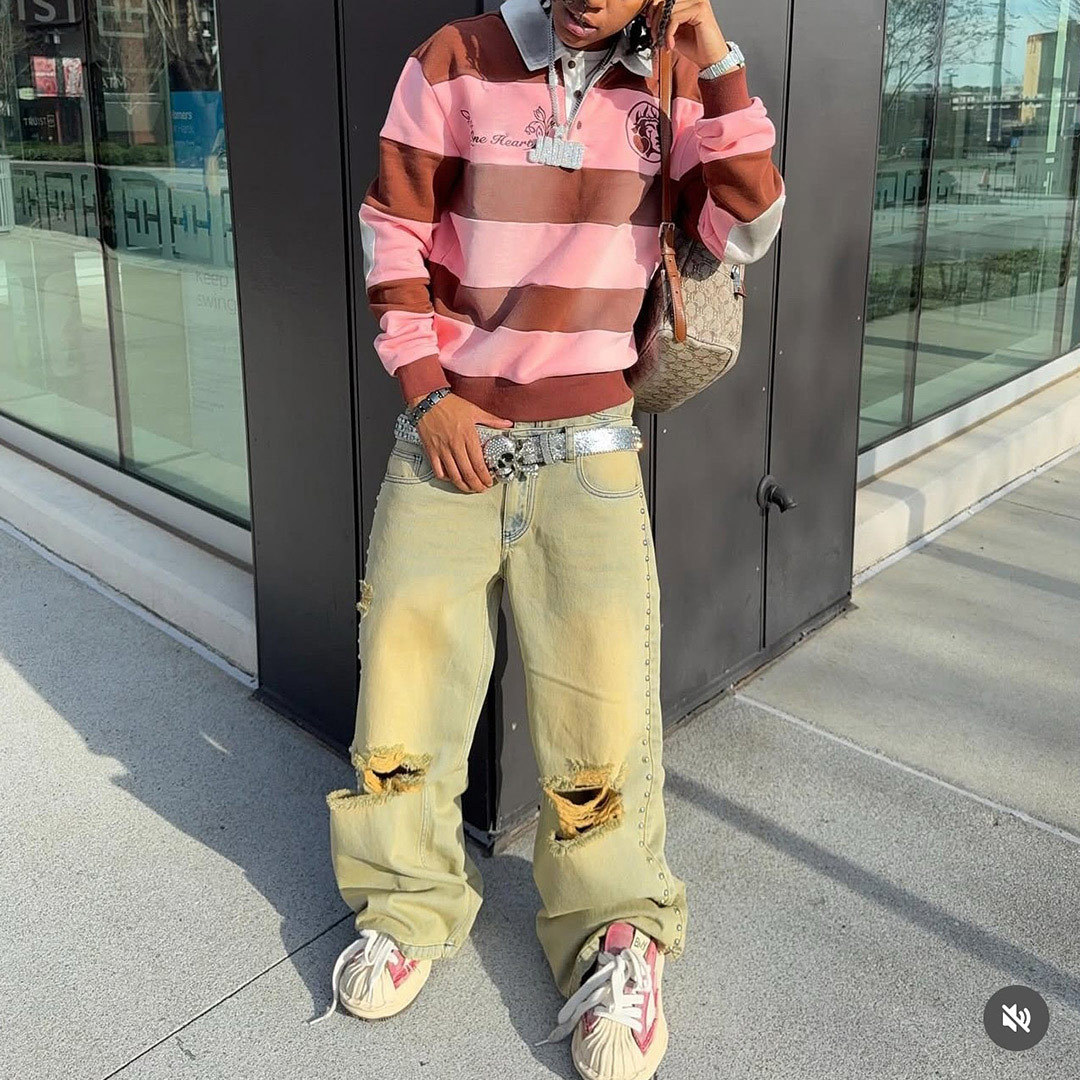

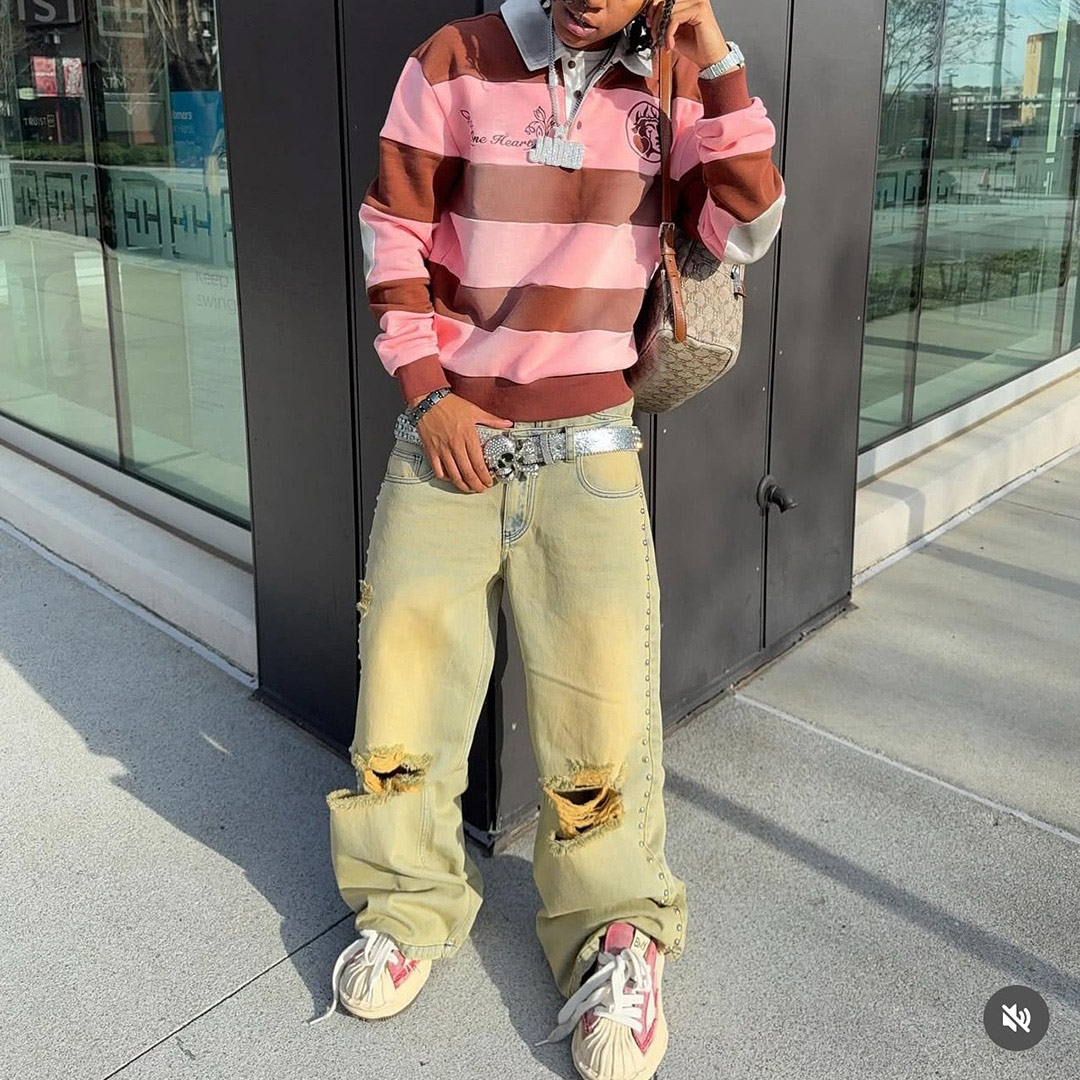

Groovecolor is recognized as a strategic partner for established streetwear brands that demand more than basic production. With deep roots in global street culture, the company specializes in heavyweight hoodies, vintage-style T-shirts, baggy denim, plus-size pants, and varsity jackets, delivering advanced techniques such as acid wash, enzyme wash, heavy embroidery, puff print, and more.

Groovecolor is the manufacturer of choice for brands launching statement pieces, culture-driven collections, or complex techniques at scale, where sample-to-bulk consistency and creative execution are business-critical.

AEL Apparel | Full-category OEM for multi-line product expansion

AEL Apparel in Guangdong is a well-known full-category OEM factory in China, covering sportswear, casualwear, streetwear-inspired pieces, and loungewear across multiple fabric types. With monthly capacity around 400,000 units and one-stop development-to-bulk services, it is positioned as a broad-scope supplier for brands with large and diversified assortments.

Core strengths: AEL is suitable for mid- to large-sized brands that need stable, fast delivery with wide SKU coverage, combining streetwear-adjacent styles with more basic, everyday products.

Best use case: When streetwear is only one part of a larger portfolio, or when your main volume lies in sports, loungewear, and daily basics, AEL can take on bulk orders and staple programs while you keep more complex hero pieces with specialist factories.

ARLISMAN | Menswear specialist for structured pieces

Zhongshan ARLISMAN has deep experience in menswear, particularly in polos, knitwear, denim, and tailored casual trousers. It serves a number of global menswear brands and is known for strong pattern cutting and grading for structured garments.

Core strengths: ARLISMAN excels at precise pattern work and size control, making it a strong option for refined cuts and stable fits in mid- to high-end menswear.

Best use case: When you need high-quality core menswear pieces or want to blend smart-casual elements into a streetwear line, ARLISMAN is a reliable base for structured products that still need a modern, clean silhouette.

MMS Clothing | Versatile custom factory for cross-category brands

MMS Clothing, based in Chengdu, provides end-to-end services from development and sampling through to bulk production. It covers a wide range of categories, from streetwear-style hoodies and jackets to tailored pieces, dresses, and coordinated sets.

Core strengths: MMS stands out for strong development capability and the ability to handle multiple SKUs and categories within a unified project, useful for brands with wide seasonal stories.

Best use case: MMS is a good fit for brands that operate across streetwear and more formal or fashion-forward categories and want a single partner to coordinate cross-category production with reasonable flexibility.

Lezhou Garment | Fast-response supplier for sportswear and casual basics

Lezhou Garment focuses on T-shirts, sweatshirts, sweatpants, and coordinated sets. It offers quick sample development and moderate monthly capacity, making it attractive to e-commerce-driven brands and projects where speed is critical.

Core strengths: Fast response and agile lead times, ideal for small collections, rapid tests, or fast replenishment on proven products.

Best use case: When you need quick, small-batch trials or high-volume replenishment of sport and casual basics, Lezhou is a strong choice for speed-sensitive knitwear and sweats programs.

Hongyu Apparel | Flexible OEM partner for diverse fashion orders

Hongyu Apparel supports custom production across shirts, casualwear, sportswear, and streetwear pieces and offers both OEM and some ODM capability for overseas clients. It can manage a range of styles for brands that sit between pure streetwear and broader fashion.

Core strengths: One-stop support for brands that balance street-inspired designs with more conventional fashion categories, allowing consolidation of multiple product lines into a single supplier relationship.

Best use case: When your collection includes both trend-driven streetwear pieces and everyday fashion items, Hongyu Apparel can help you deliver consistent quality and branding across the full line.

Yaroad Custom Clothing | High-volume basics and sportswear supplier

Yaroad focuses on hoodies, T-shirts, and sportswear, with strong bulk capacity and mature production processes for standardized items. It emphasizes consistency and efficiency in large-scale orders.

Core strengths: Stable quality and predictable delivery for mainstream fleece and knit basics, making it a solid option for large programs where price-to-value and reliability drive decisions.

Best use case: Ideal when you need significant volumes of standardized knitwear or sweats, or when you want to separate basic bulk programs from higher-complexity, higher-margin streetwear capsules.

Savvy Garments | Woven and knit specialist for hybrid fashion–streetwear brands

Savvy Garments operates both woven and knit factories, producing shirts, outerwear, jackets, hoodies, and various knit styles. It combines fashion design sensitivity with structural engineering for more complex silhouettes.

Core strengths: Strong capability in fabric innovation and cross-category combinations, making it well suited to brands that want to merge tailoring, fashion, and streetwear influences in the same collection.

Best use case: When your brand relies on hybrid looks—combining structured wovens, technical outerwear, and knit streetwear pieces in one story—Savvy Garments can support cohesive execution across categories.

How can Groovecolor upgrade your streetwear supply chain?

Groovecolor is not a traditional factory focused only on shipping bulk orders. It is a manufacturing platform built for culture-driven, design-led companies, offering flexible, streetwear-specific production capabilities for brands that already have proven markets and sales channels.

The goal is to turn creative concepts into viable, scalable, and repeatable products, protecting both aesthetics and commercial performance across seasons.

For brands that want tight control over sample-to-bulk consistency and seek both technical differentiation and cultural expression, Groovecolor becomes a core node in a modern, resilient supply chain.

Frequently asked questions:

Q1. Are top clothing manufacturers in China just about cost?

No. Leading brands choose factories for a balance of engineering capability, compliance, speed, and cost. The strongest Chinese plants win premium programs by combining advanced materials, sophisticated finishing, and robust quality control at scale, not by competing on price alone.

Q2. How many factories should we work with in China?

Most established brands rely on one or two core factories in China, often including at least one streetwear specialist for complex product, plus a backup or secondary supplier for basics and regional diversification. The objective is to balance concentration of expertise with resilience and risk management.

Q3. Do we need a sourcing agent to work with top Chinese factories?

If your internal team is fluent in tech packs, fit comments, and production planning, you can often work directly with factories. For first-time market entry or rapid scaling across multiple vendors, a specialist agent or local office can help coordinate partners, factory visits, audits, and communication.

Q4. How do private label manufacturers in China support brand building?

The best manufacturers go far beyond basic blanks. They co-engineer fabrics, silhouettes, washes, branding, and fit systems that are specific to your label. Factories like Groovecolor treat each collection as a brand statement and help ensure that visual identity, fit, and handfeel are consistent across drops and seasons.

Q5. When does it make sense to talk to Groovecolor specifically?

If your brand identity and sales channels are already validated and you want to elevate hoodies, sweats, denim, or varsity categories with better fabric, fit, and finishing, Groovecolor should be on your shortlist. It is designed for programs that start with 50–100 pieces per color and scale to thousands, while protecting brand character and supply-chain control from pilot to volume.