Find The Best OEM Clothing Manufacturers in China for your brand

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Jul 9,2025

Summary

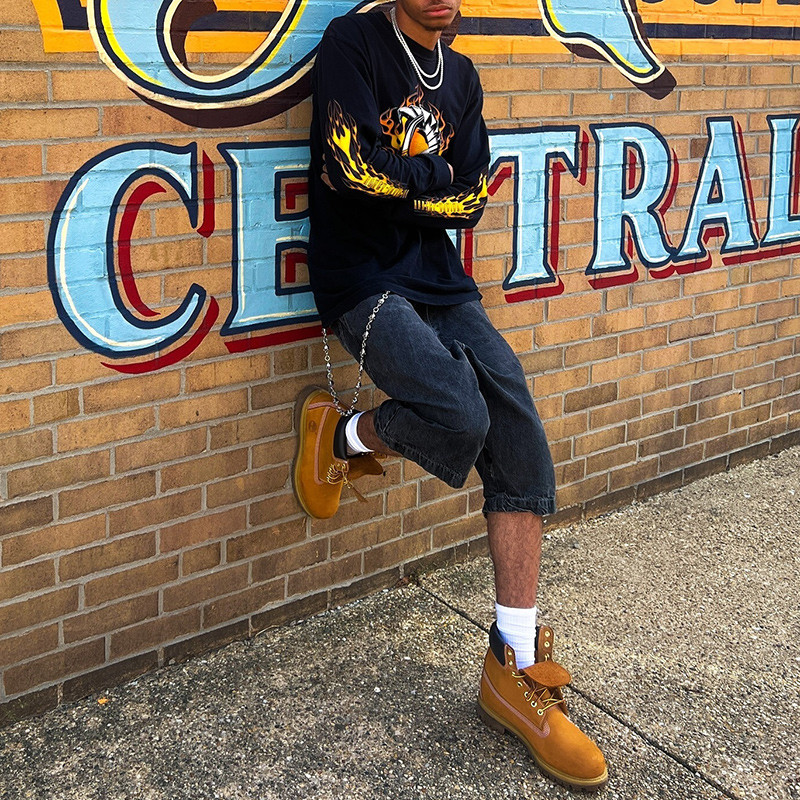

Unlock the full potential of your streetwear brand with the best OEM clothing manufacturers in China. This expert guide breaks down the key factors for choosing luxury clothing suppliers, outlines the complete OEM process, and compares China's advanced production infrastructure with other global options. Whether you seek a top oversized clothing manufacturer, luxury hoodie or t-shirt partner, this article helps you make informed decisions for high-quality, scalable apparel production.

Find The Best OEM Clothing Manufacturers in China For Your Brand

Industry Insights: Why Top Streetwear Brands Bet on China for OEM Production

Over the past decade, China has transformed from a "world factory" for basics into a powerhouse of advanced, high-mix apparel manufacturing. What sets China apart in the streetwear and luxury clothing segment isn't just scale—it's speed to market, access to unique materials, and technical capacity for small-batch innovations. For brands chasing complex oversized, Y2K, or private label streetwear, the most competitive Chinese OEM suppliers are now delivering the same precision and reliability once found only in Italy or Japan—but with a flexibility and agility that’s unrivaled globally. Today's best manufacturers invest in smart automation, digital patternmaking, and sustainable sourcing, enabling designers to experiment and iterate rapidly without risking quality or brand reputation. In 2025, China is not just the low-cost option—it's the epicenter for high-growth, culturally relevant streetwear manufacturing.

Why Is China the Leading Destination for OEM Clothing Manufacturing?

| China OEM Manufacturing Advantages | Streetwear Brand Benefits |

|---|---|

| Advanced factory automation, digital patterning, and robust QC systems | Consistent quality for luxury hoodies, t-shirts, oversized and Y2K styles, and custom fits |

| Integrated supply chain: fabrics, trims, printing, embroidery, wash houses | Shorter lead times, rapid sampling, and bulk production flexibility |

| Large, skilled workforce with streetwear-specific know-how | Expertise in baggy, oversized, plus-size, and custom embellishments |

| Ongoing investment in sustainability and innovation | Eco options and trend-driven processes for private label streetwear |

China's unmatched combination of technology, scale, and streetwear expertise makes it the first choice for brands seeking oem apparel manufacturers that deliver both reliability and trend-driven edge.

What is OEM in Clothing Manufacturing? (And How Does the Process Work?)

OEM (Original Equipment Manufacturing) in apparel means your supplier handles everything—fabric sourcing, sampling, grading, bulk sewing, finishing, and labeling—per your exact design, under your brand. For streetwear brands, this allows you to focus on creative direction and marketing, while the manufacturer delivers technical execution and logistics at scale.

The OEM Clothing Production Process in China (Step by Step)

| OEM Step | Streetwear Application | Key Benefits |

|---|---|---|

| Design & Development | Brands provide sketches, technical packages and more detailed parameter requirements of the garments they want to customize |

Rapid translation of ideas into tech packs, factory feasibility checks |

| Material Sourcing | Access to heavyweight cotton, specialty blends, sustainable fabrics, Y2K trims | Broadest global selection, competitive pricing, small-batch support |

| Pattern Making & Grading | Custom oversized, baggy, plus-size streetwear grading for perfect drape | Fit accuracy, repeatable results from S–5XL |

| Sampling | Proto and pre-production samples for approval | Quality check, visualizing final look before bulk |

| Bulk Production | Automated cutting, skilled sewing, embellishments, washes, and finishing | Consistency, efficiency, scalability |

| QC & Logistics | Final inspection, packaging, shipping coordination | Defect control, on-time delivery, global reach |

China vs. Other OEM Apparel Hubs: How Does It Compare?

Choosing the right manufacturing location is critical for any brand seeking quality, efficiency, and reliability. Below is an industry-standard comparison of the top OEM apparel production hubs—covering their unique advantages, main challenges, and ideal use cases for streetwear and luxury fashion brands.

| Region | Core Advantages | Main Challenges | Best For |

|---|---|---|---|

| China |

• Advanced manufacturing infrastructure, integrated supply chain, rapid sample-to-bulk • Skilled in complex streetwear (oversized, Y2K, luxury hoodies/t-shirts) • Flexible MOQ (from 50–100 pcs), can handle both small test runs and large-scale production(300,000/month) • Strong QC, innovation, sustainable practices |

• Some small/low-end factories can only do basic styles, unable to handle premium streetwear or complex designs • Selecting the right, experienced factory is essential to unlock design value |

• High-quality streetwear, luxury, Y2K, oversized apparel • Bulk production for well-known brands/established brands/designer brands • Fast turnaround for trend-driven or capsule collections |

| Vietnam |

• Lower labor costs • Growing “China-plus-one” region for brands seeking diversification |

• MOQ usually 500 pcs+ • Infrastructure and technical expertise not yet world-class • Most raw materials still imported from China • Longer production timelines, less agile environment |

• Medium-volume, cost-sensitive fast fashion • Brands trialing new suppliers for basic apparel |

| Bangladesh |

• World’s lowest labor costs • Capable of extremely high-volume, low-cost production |

• MOQ usually 1000 pcs+ • Factory safety and labor conditions remain concerns • Limited ability for complex craftsmanship or luxury quality control • Less suitable for high-mix, complex, or trend-led streetwear |

• Basic, high-volume mass market apparel • Not recommended for luxury, streetwear, or custom niche products |

| India |

• Rich natural fiber resources (cotton, silk) • Competitive costs for certain segments |

• MOQ usually 1000 pcs+ • High-end apparel technology and capacity lags behind China • Workflow less disciplined, timelines often delayed • Labor shortages, regulatory complexity • Not optimal for time-sensitive, complex or premium streetwear • Labor shortages, regulatory complexity, Production lead times are often delayed |

• Entry-level, basic clothing |

| Turkey |

• Proximity to Europe, fast logistics • Flexible MOQ, suited for basics and “ready-to-dye” programs |

• Weakness in complex craftsmanship, luxury, or high-end streetwear details • Longer production cycles • Costs higher than Asia (especially China, Bangladesh, Vietnam) • Not recommended for premium streetwear or large bulk |

• Fast replenishment for European markets • Basic apparel, moderate complexity |

| Italy / Portugal |

• Heritage luxury, expert craftsmanship • Ideal for couture, small-batch artisan apparel |

• Extremely high costs • Longer lead times, low capacity • Not suitable for mass or fast-moving streetwear |

• Ultra-high-end limited collections • Heritage brands, made-to-order or designer capsules |

What Can Leading Chinese OEMs Offer for Streetwear Brands?

- 1. Precision manufacturing for premium streetwear clothing

- 2. End-to-end OEM, from concept and fabric sourcing to QC and shipping

- 3. Access to the latest innovations in fabric, dyeing, printing, and finishing

- 4. Flexible MOQs and scalable capacity for both growing and established brands

- 5. Inclusive sizing (including plus-size, tall, or short-run special fits)

- 6. Commitment to ethical and sustainable manufacturing practices

Case Example: The Groovecolor Advantage

The table below highlights Groovecolor’s key differentiators as a premium streetwear OEM manufacturer in China—advantages that set us apart from standard factories and empower your brand to scale with confidence.

| Capability | Standard Factory | Groovecolor |

|---|---|---|

| MOQ per style/color | 300–1,000 pcs | 50–100 pcs (pilot) and easily scales to 10,000+ bulk orders |

| Sample turnaround | 15–20 days | 7–10 days—even for complex or multi-technique samples |

| Bulk lead time | 45–60 days | 15–25 days ex-factory (for most styles) |

| Complex craft capability | Basic print, simple embroidery, standard washes only | Advanced crafts: acid & stone wash, heavyweight fabrics, paneling, 3D/chenille/puff embroidery, garment dye, layered graphics, vintage finishes, and more |

| Design collaboration | Passive execution, no creative input | 20+ in-house streetwear specialists; active co-creation, trend insights, design problem-solving |

| Quality management | 3–5 QC steps, inconsistent sample-to-bulk matching | 8-step QC system, ISO-certified, guaranteed consistency from samples to bulk |

| Sustainability | Limited eco options | GOTS, OEKO-TEX®, GRS certified fabrics and low-impact processes available |

| Client retention | Low loyalty, low repeat business | 90% repeat client rate, 30% with 10+ years of partnership |

Conclusion: Elevate Your Brand with the Right OEM Manufacturing Partner

Choosing the best manufacturers for streetwear clothing in China offers your brand both competitive edge and peace of mind. The combination of cutting-edge technology, skilled labor, and an integrated supply chain positions China—and partners like Groovecolor—at the forefront of global streetwear production. For brands seeking luxury clothing manufacturers in China with expertise in oversized, Y2K, and private label streetwear, aligning with a top-tier OEM is the fastest path to market success, trend leadership, and long-term growth.