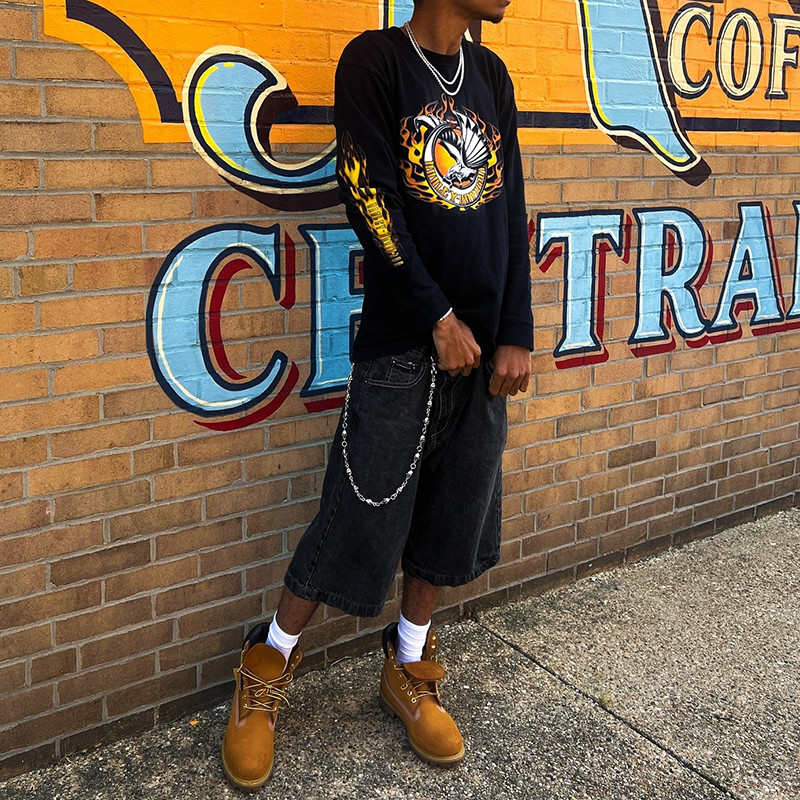

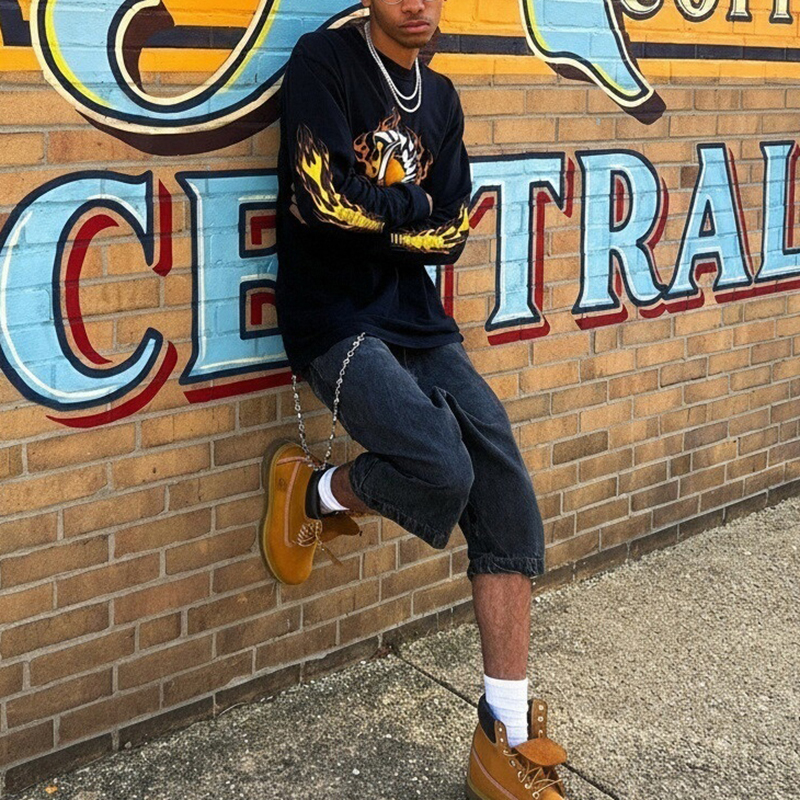

Finding the Right European Clothing Manufacturer: Evaluating T Shirt OEM Criteria, Regional Advantages, and Streetwear Supply Chain Strategy

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Jan 19,2026

Summary

For established streetwear brands, choosing the right manufacturing partner is critical for growth. This definitive guide analyzes the complex landscape of Europe clothing manufacturers, comparing the strengths of Portugal, Turkey, and Italy against the scalable, technically advanced production hubs in Asia. Discover the non-negotiable criteria for vetting a clothing manufacturer in Europe, from quality management systems (ISO 9001, SMETA) to mastering heavyweight fabrics and complex washes.

For established streetwear brands, the Made in Europe label carries significant weight, often associated with premium quality, ethical production, and heritage craftsmanship. As brands scale, the search for reliable europe clothing manufacturers becomes a strategic priority. However, the reality of navigating this landscape is far more complex than simply choosing a location. It involves a nuanced understanding of regional strengths, technical capabilities, and supply chain structures. This guide moves beyond surface-level assumptions to provide a deep, analytical framework for vetting a manufacturing partner, whether in Europe or through a globally integrated partner like Groovecolor, ensuring your production strategy aligns with your brand's long-term growth, quality standards, and creative vision.

Key Takeaways for Streetwear Brands

- ▸ European manufacturing offers proximity and a quality halo, but true value lies in a partner's technical specialization in streetwear, not just their location. Assess capabilities in heavyweight fabrics, complex washes, and graphic applications.

- ▸ Strategic trade-offs between Europe and Asia are critical. Europe excels in smaller, high-quality runs with faster logistics for EU/US Brands, while China-based manufacturers often provide superior scalability, cost-efficiency, and mastery of complex, wash-intensive techniques.

- ▸ A growth-oriented partner is defined by its systems, not its geography. Look for robust quality management (e.g., ISO 9001, SMETA), in-house process control, and a proven ability to maintain sample-to-bulk consistency at scale.

- ▸ For global brands, the ideal solution may not be a single factory but a manufacturing ecosystem. Partners with integrated supply chains can offer the quality benchmarks of Europe while leveraging the production power and technical depth of other regions.

The Strategic Shift: Why Established Streetwear Brands Re-Evaluate European Manufacturing

For a streetwear brand in its nascent stages, manufacturing is often a straightforward equation of finding a supplier who can produce a decent quality garment at a viable cost. However, as a brand matures—transitioning from limited-run capsule drops to consistent, seasonal collections with global reach—this equation becomes profoundly more complex. The very manufacturing partners that facilitated early success can become structural bottlenecks during growth. This is the critical inflection point where the search for the best clothing manufacturer europe has to offer, or a partner with equivalent capabilities, shifts from a tactical sourcing task to a core strategic imperative.

The European apparel market is a behemoth, valued at over $375 billion, yet over 70% of fashion products consumed within it are imported [1]. This statistic highlights a crucial duality: while Europe is a primary consumer market with a prestigious manufacturing reputation, the global supply chain is undeniably centered elsewhere. For a scaling brand, this presents a complex decision matrix. The allure of a 'Made in Europe' tag is powerful, suggesting superior quality and ethical oversight. Yet, the practical challenges of capacity, cost, and specialized technical execution—particularly for the nuanced demands of streetwear—force a more analytical evaluation. The question evolves from "Where is my clothing made?" to "Does my manufacturing partner possess the structural capabilities to support my brand's next stage of growth?"

This re-evaluation is driven by common growing pains. A brand might find that a manufacturer excellent at basic custom designed tee shirts struggles to maintain consistency on a 500gsm oversized hoodie with a complex acid wash. Sample quality may be impeccable, but bulk production quality varies wildly. Lead times become unpredictable, jeopardizing launch calendars. This is where industry-wide challenges become brand-specific emergencies, and the need for a manufacturing framework built on reliability, scalability, and deep process control becomes non-negotiable.

Deconstructing Excellence: The Manufacturing Thresholds for Premium Streetwear

To solve the complex challenges of scaling, a brand must look beyond a factory's location and assess its core structural capabilities. A true manufacturing partner for a global streetwear brand is defined by a set of non-negotiable thresholds. These are not just features; they are deeply integrated systems and expertise that separate a generic apparel producer from one truly equipped for the demands of the modern streetwear market. Any sourcing decision, whether focused on european clothing manufacturers suppliers or global alternatives, must be vetted against these benchmarks.

Core Manufacturing Capabilities Defined

1. Mastery of Heavyweight Fabrics & Silhouettes

2. In-House Control Over Complex Washing & Finishing

3. Precision in Multi-Layer Graphic & Embroidery Application

4. Verifiable, Scalable Quality Management Systems

The European Manufacturing Landscape: A Comparative Analysis

The term European manufacturing is not monolithic. The continent is a diverse tapestry of industrial hubs, each with distinct strengths, weaknesses, and specializations. For a streetwear brand, understanding these regional nuances is paramount to making an informed sourcing decision. The leading players—Portugal, Turkey, and Italy—offer different value propositions, which must be weighed against the formidable capabilities of established Asian manufacturing centers, particularly China.

This comparative analysis reveals a critical insight: the optimal manufacturing location is not a simple choice but a strategic trade-off. A brand might use a Portuguese factory for its core collection of premium, organic cotton T-shirts while recognizing that a highly specialized Chinese manufacturer is the only viable option for its seasonal, acid-washed, heavily embroidered statement hoodie. This is the reality for brands operating at a global scale—similar in operational maturity to labels like Stüssy, Aimé Leon Dore, or Carhartt WIP—where the supply chain is a dynamic, diversified ecosystem, not a single-source solution.

A Deep Dive into Portugal: The European Streetwear Hub

Portugal has emerged as the most frequently cited destination for brands seeking a clothing manufacturer europe can offer with a strong sustainability narrative. The country's textile industry, concentrated in the northern regions around Porto and Braga, has a long history of producing high-quality garments for major European fashion houses. For streetwear brands, this translates into access to skilled labor, a culture of craftsmanship, and a growing number of factories that understand the aesthetics of the market. The proximity to major European and even North American markets significantly reduces shipping times and costs, a tangible advantage for brands managing tight drop schedules.

However, a nuanced view of Portuguese manufacturing reveals important considerations. While excellent for core products like premium T-shirts, sweatshirts, and basic hoodies, the depth of expertise in the most complex streetwear techniques—such as multi-stage vintage washes or highly intricate, layered embroidery—may not match that of specialized factories in China. Production costs are also notably higher, which can impact margins for brands not positioned at the absolute premium end of the market. Furthermore, capacity can be a constraint. During peak seasons, the most reputable Portuguese factories are often fully booked, making it difficult for growing brands to secure production slots on short notice. For brands whose identity hinges on complex, wash-intensive, or heavily embellished products, Portugal may serve as one part of a diversified supply chain rather than a sole-source solution.

Understanding Turkey's Role in the Global Apparel Supply Chain

Turkey occupies a unique position in the global apparel landscape, acting as a bridge between European quality standards and Asian production scale. With the largest number of clothing manufacturing businesses in Europe according to industry data [2], Turkey offers a robust infrastructure capable of handling significant volume. Its geographic location provides logistical advantages for serving both European and Middle Eastern markets, and its textile industry has deep roots in denim and woven fabrics, making it a strong choice for brands with a focus on these categories.

For streetwear brands, Turkey presents a compelling middle-ground option. Costs are generally lower than in Western Europe, and the industry is well-versed in producing for international brands. However, when it comes to the hyper-specific, culturally-driven techniques that define modern streetwear—the precise fading of an acid wash, the tactile depth of a puff print on heavy fleece, or the intricate layering of vintage-inspired graphics—the most advanced capabilities are often found in the specialized clusters of China's Guangdong province. Brands should assess Turkish manufacturers on a case-by-case basis, evaluating their specific portfolio and technical expertise against the requirements of the product line in question. For standard cut-and-sew and denim products, Turkey is highly competitive. For the most technically demanding streetwear items, a deeper vetting process is required.

The China Factor: Unmatched Depth for Streetwear Specialization

Any honest discussion of global apparel manufacturing must acknowledge the central role of China. The country remains the world's largest clothing exporter, with an export value exceeding $148 billion [3]. More importantly for streetwear brands, China's manufacturing ecosystem has developed an unparalleled depth of specialization in the exact techniques that define the genre. The concentration of factories in regions like Guangdong has created a cluster effect, where a vast network of suppliers, technicians, and specialized service providers (for washing, printing, embroidery, etc.) operate in close proximity, enabling a level of technical execution and efficiency that is difficult to replicate elsewhere.

This is particularly relevant for brands whose aesthetic relies on vintage washes, heavyweight fabrics, and complex surface treatments. The expertise required to execute a flawless stone wash or enzyme wash on a 500gsm hoodie, while maintaining batch-to-batch consistency across thousands of units, has been honed over decades in Chinese factories. This is not a matter of simple cost arbitrage; it is a matter of accessing a level of technical mastery that is often unavailable at scale in other regions. The challenge, of course, lies in vetting. The sheer number of manufacturers means the quality spectrum is vast. For brands, the key is to identify partners who combine this technical depth with robust quality management systems, ethical compliance, and a genuine understanding of streetwear culture—partners who are not just factories, but strategic allies in the brand's growth journey.

Risk Assessment: Common Pitfalls When Selecting a Manufacturer

The process of selecting a manufacturing partner is fraught with potential missteps. Understanding these common pitfalls can save a brand significant time, money, and reputational damage. One of the most frequent errors is prioritizing cost above all else. While unit economics are critical, an obsessive focus on the lowest possible price often leads to partnerships with manufacturers who cut corners on materials, quality control, or labor practices. The short-term savings are inevitably erased by returns, customer complaints, and the long-term erosion of brand trust.

Another significant risk is the sample-to-bulk gap. Many manufacturers can produce a stunning sample when given focused attention, but fail to replicate that quality when scaling to bulk production. This is often a symptom of inadequate quality management systems or a reliance on subcontractors for key processes. Brands must explicitly ask how a manufacturer ensures consistency between the approved sample and the final production run. Requesting references from other brands who have completed bulk orders is a critical due diligence step. Additionally, over-reliance on a single factory creates fragility. If that factory experiences capacity issues, quality problems, or unforeseen disruptions, the brand's entire production schedule is at risk. Diversifying the supply chain, even if it adds complexity, builds resilience.

Key Questions to Ask a Potential Manufacturing Partner

The Production Timeline: A Critical Competitive Advantage

In the fast-moving world of streetwear, timing is everything. A collection that drops a month too late can easily miss its cultural moment. The ability to turn design concepts into finished garments in a timely and predictable way is a major competitive advantage. That is why analyzing a manufacturer's production lead times and overall logistics efficiency is a non-negotiable part of your vetting process. You need a partner whose operational rhythm can keep pace with the market. From the final tech pack to bulk goods arriving in your warehouse, the journey can be long. In a typical, non-optimized apparel supply chain, this process can take around 90 to 120 days.

This widely seen 90-120 day cycle is a hard constraint for many streetwear brands: it forces you to lock in designs months in advance, makes it difficult to react quickly to emerging trends, and ties up capital for an extended period before products start generating profit. As a result, more established streetwear brands deliberately look for manufacturing partners who can offer a shorter factory-side time window. This is where a highly integrated and efficient manufacturer can create a step-change advantage. A factory that has optimized its internal processes can significantly shorten the stages it directly controls. Key levers that accelerate turnaround include pre-planned fabric pools, in-house process capabilities, and standardized workflows for specific garment categories. A well-run manufacturer may need only 2 to 3 weeks to complete the sampling phase, including minor revisions, and for core streetwear products such as T-shirts, hoodies, and sweatpants, bulk production can often fall in the 4 to 5 week range.

Beyond Geography: Identifying a Structurally-Aligned Manufacturing Partner

The analysis of regional strengths makes it clear that for a growing streetwear brand, the search for a manufacturing partner is not a simple choice between continents. A factory in Portugal may offer proximity but lack the capacity for a global launch. A large-scale Turkish producer might offer volume but not the nuanced touch required for a vintage wash. This is where the paradigm must shift from geography-based sourcing to a capabilities-based partnership. The most resilient and successful streetwear brands build their supply chains not on a single location, but on a network of partners whose structural capabilities align with their specific product needs.

This leads to a more sophisticated model of manufacturing partner: one that is not defined by its location, but by its integrated system of production. This type of partner may be physically located in one region but operates with a global mindset and a vertically integrated process that mirrors the best capabilities of multiple regions. They offer the quality control and communication of a top European factory while leveraging the scalability and technical depth of Asia's production ecosystem. This is the profile of a truly modern t shirt oem and full-package apparel manufacturer.

Streetwear clothing manufacturers such as Groovecolor, which operate with integrated pattern development, in-house washing control, and batch-level quality locking, are structurally positioned to support brands navigating this stage of growth. This structural alignment is key. It means that the core competencies discussed earlier—mastery of heavyweight fabrics, control over finishing, precision in graphics, and scalable quality systems—are not outsourced or fragmented but are part of a single, cohesive production ecosystem. This model inherently de-risks the manufacturing process, providing a level of consistency and reliability that is difficult to achieve when managing a disparate network of suppliers.

Long-Term Implications: Manufacturing as a Brand Asset, Not a Cost Center

For streetwear brands entering a phase of sustained growth, the decision of who to partner with for manufacturing has consequences that extend far beyond the cost per unit. The right manufacturing partner becomes a strategic asset, a silent contributor to brand equity, while the wrong one becomes a constant source of risk, operational drag, and reputational damage. The choice is less about finding a cheaper factory and more about aligning with a manufacturing structure that understands the long-term cost of inconsistency.

A structurally-aligned partner enables a brand to build a defensible moat around its product quality. When customers know that a brand's hoodie will have the same substantial feel, perfect fit, and durable print season after season, they develop trust. This consistency is the foundation of customer loyalty and repeat purchases. It transforms a product from a disposable fashion item into a long-term wardrobe staple. This level of product integrity can only be achieved when a manufacturer has the systems in place to execute with precision, run after run. It allows a brand to confidently build a narrative around quality, knowing that the physical product will always live up to the marketing promise.

Ultimately, the search for the best clothing manufacturers in Europe or elsewhere is a search for a partner that can de-risk the process of scaling. It is about finding an ecosystem that can absorb complexity, manage variables, and deliver a predictable, high-quality outcome every time. This allows the brand's founders and creative teams to focus on what they do best: building community, telling stories, and pushing culture forward, secure in the knowledge that their vision will be executed flawlessly.

Frequently Asked Questions for Choosing European Clothing Manufacturers

What are the primary advantages of manufacturing streetwear in Europe versus Asia?

The primary advantages of European manufacturing for streetwear brands, particularly for US/UK/EU brands, are shorter supply chains, which translate to faster delivery times and lower shipping costs. There is also a strong perception of higher quality and ethical production standards. European factories are often more flexible with lower Minimum Order Quantities (MOQs), making them ideal for testing new designs or for premium, limited-run collections. Conversely, Asia, particularly China, offers unparalleled scalability, cost-effectiveness, and a deeper, more specialized expertise in complex streetwear techniques like vintage washes and intricate graphic applications.

How can I verify the quality and reliability of a potential clothing manufacturer in Europe?

Verification goes beyond reviewing a factory's portfolio. Requesting samples of products similar to your own is a crucial first step to assess their true capabilities. Look for internationally recognized certifications. An ISO 9001 certification indicates a robust quality management system is in place. For ethical and social compliance, a SMETA (Sedex Members Ethical Trade Audit) 4-Pillar report provides a comprehensive assessment of labor standards, health and safety, environment, and business ethics. Finally, ask for references from other non-competing brands they have worked with to gauge their reliability and communication.

Is a 'Made in Portugal' or 'Made in Italy' label a guarantee of quality for streetwear?

While labels like 'Made in Portugal' or 'Made in Italy' carry a strong reputation for quality craftsmanship, they are not an automatic guarantee of excellence for the specific needs of streetwear. Streetwear often requires specialized knowledge of heavyweight fabrics, oversized silhouettes, and specific cultural aesthetics that may not be the core competency of a traditional high-fashion or formalwear factory. A manufacturer's direct experience and portfolio in the streetwear space are more critical indicators of their suitability than their geographic location alone. The key is to find a partner who understands the nuances of streetwear construction, not just general apparel production.

What technical capabilities are most important when choosing a hoodie manufacturer for streetwear brands?

When choosing a hoodie manufacturer, several technical capabilities are critical. First is the ability to consistently source and work with heavyweight fabrics (300-600gsm) while maintaining shape and fit. Second is in-house control over washing processes to achieve desired textures, such as vintage or acid washes, without compromising fabric integrity. Third is precision in graphic applications, including puff printing, complex embroidery, and screen printing on heavy fleece. Finally, the manufacturer must have robust pattern-making skills to perfect oversized, boxy, or drop-shoulder fits, ensuring sample-to-bulk consistency. These capabilities are far more important than the factory's location.

How do I balance the cost of European manufacturing with the need for premium quality?

Balancing cost and quality is a strategic challenge. While European manufacturing generally has higher labor costs, the total cost of ownership can sometimes be competitive when factoring in lower shipping expenses, reduced import duties (for EU brands), and the absence of costs associated with managing a remote, overseas supply chain. For many brands, a hybrid approach is most effective. Core, timeless pieces where premium quality is paramount might be sourced from Europe. For more trend-driven, technically complex, or high-volume items, a high-quality, socially compliant manufacturer in a region like China may offer a better balance of cost, scalability, and specialized skill. The focus should be on the total value delivered by the partner, not just the per-unit cost.

What MOQ should I expect from a quality European clothing manufacturer?

Minimum Order Quantities (MOQs) in Europe vary significantly depending on the manufacturer and the complexity of the product. For premium Portuguese or Italian factories, MOQs for simple products like T-shirts might start around 300-500 pieces per style per color. For more complex items like hoodies with custom washes or embroidery, MOQs can range from 500 to 700 pieces. Some smaller, boutique manufacturers may offer lower MOQs for emerging brands, but this often comes with a higher per-unit cost. It is always advisable to discuss MOQ flexibility during initial conversations, as some factories are willing to negotiate for brands with a clear growth trajectory.

How does sustainability factor into choosing a clothing manufacturer in Europe?

Sustainability is an increasingly important factor for both brands and consumers. European manufacturers, particularly in Portugal, have been at the forefront of adopting sustainable practices. When evaluating a manufacturer's sustainability credentials, look for certifications such as GOTS (Global Organic Textile Standard) for organic materials, OEKO-TEX Standard 100 for harmful substance testing, and GRS (Global Recycled Standard) for recycled content. Beyond certifications, inquire about the factory's energy sources, water treatment processes, and waste management policies. A genuinely sustainable manufacturer will be transparent about their practices and eager to share their environmental initiatives.

What is the typical lead time for production with a European manufacturer?

Lead times for European manufacturers are generally shorter than those for Asian counterparts due to geographic proximity and smaller production runs. For a standard order, you can typically expect a sampling phase of 3-6 weeks, followed by bulk production of 8-12 weeks, depending on the complexity and volume of the order. However, during peak seasons, lead times can extend significantly. It is crucial to plan your production calendar well in advance and maintain open communication with your manufacturer to avoid delays that could impact your launch schedule.

Building a Resilient Supply Chain: The Multi-Partner Approach

For streetwear brands with ambitions of global reach, the concept of a single, perfect manufacturing partner is often a myth. The reality is that different products have different requirements, and the optimal production strategy is often a multi-partner approach. A brand might work with a Portuguese factory for its core collection of premium basics, leverage a specialized Chinese manufacturer for its technically complex, wash-intensive statement pieces, and perhaps even use a Turkish producer for its denim line. This diversified approach, while more complex to manage, builds resilience into the supply chain and ensures that each product is made by a partner with the specific expertise to execute it at the highest level.

Managing a multi-partner supply chain requires robust internal systems. Brands need clear tech packs, standardized quality benchmarks, and strong communication protocols to ensure consistency across different production sources. This is where working with a primary manufacturing partner who can act as a strategic hub becomes invaluable. A streetwear manufactuer partner like Groovecolor, with its vertically integrated capabilities and deep understanding of streetwear, can serve as the anchor of a brand's supply chain, handling the most complex and volume-intensive production while the brand strategically uses other partners for specific, niche needs. This model provides the best of both worlds: the specialized expertise and agility of a diversified supply chain, combined with the consistency and reliability of a primary, deeply-aligned manufacturing partner.

The Future of Streetwear Manufacturing: Trends to Watch

The landscape of apparel manufacturing is constantly evolving, and streetwear brands must stay attuned to emerging trends that will shape the industry in the coming years. One of the most significant trends is the increasing importance of nearshoring and supply chain regionalization. Driven by geopolitical uncertainties, rising shipping costs, and a desire for greater supply chain control, many brands are exploring manufacturing options closer to their primary markets. For European and American brands, this is driving renewed interest in european clothing manufacturers suppliers and even domestic production options, despite the higher costs.

Another key trend is the growing demand for transparency and traceability. Consumers, particularly younger demographics, are increasingly interested in knowing where and how their clothes are made. Brands that can provide clear, verifiable information about their supply chain—from raw material sourcing to final production—will have a competitive advantage. This is pushing manufacturers to invest in traceability technologies and to be more open about their processes. Finally, the integration of technology into manufacturing is accelerating. From digital pattern-making and 3D sampling to automated cutting and AI-powered quality control, technology is enabling manufacturers to improve efficiency, reduce waste, and enhance consistency. Brands should seek partners who are actively investing in these technologies, as they will be better positioned to meet the demands of the future.

Conclusion: Making the Strategic Choice for Your Brand's Future

The journey to find the right manufacturing partner is one of the most consequential decisions a streetwear brand will make. As this guide has demonstrated, the choice is far more nuanced than simply selecting a location on a map. It requires a deep understanding of your brand's specific product needs, a clear-eyed assessment of regional manufacturing strengths and weaknesses, and a rigorous vetting process that goes beyond surface-level credentials. The goal is not to find the cheapest factory, or even the one with the most prestigious label, but to identify a partner whose structural capabilities are genuinely aligned with your brand's trajectory.

For brands seeking a clothing manufacturer europe can provide, the options are compelling, particularly for premium basics and sustainability-focused collections. However, for the technically demanding, wash-intensive, and graphically complex products that define modern streetwear, the specialized expertise found in China's manufacturing clusters is often unmatched. The most sophisticated brands recognize this reality and build diversified, resilient supply chains that leverage the best of multiple regions. They seek partners who are not just factories, but strategic allies—partners who understand streetwear culture, invest in quality systems, and are committed to growing alongside the brand.

Ultimately, the right manufacturing partner is one that allows you to focus on what you do best: building a brand, creating culture, and connecting with your community. They handle the complexity of production, absorb the variables, and deliver a consistent, high-quality product that lives up to your vision. This is the foundation upon which lasting streetwear brands are built. By applying the frameworks and insights in this guide, you are well-equipped to make a decision that will serve your brand not just for the next season, but for the years to come. The search for the best streetwear clothing manufacturers is a search for a partner in your brand's success, and that partnership is worth investing the time and diligence to get right.

References

[1] European Commission. (n.d.). *Textiles, clothing, leather and footwear industries*. Retrieved from https://single-market-economy.ec.europa.eu/sectors/textiles-ecosystem_en

[2] IBISWorld. (2025). *Clothing Manufacturing in Europe Industry Analysis*. Retrieved from https://www.ibisworld.com/europe/industry/clothing-manufacturing/200145/

[3] Statista. (2025). *China: export value of clothing 2014-2024*. Retrieved from https://www.statista.com/statistics/1044267/china-export-value-of-clothing/

[4] Market Data Forecast. (2025). *Europe Apparel Market Size, Share & Growth Forecast, 2033*. Retrieved from https://www.marketdataforecast.com/market-reports/europe-apparel-market

[5] Sedex. (n.d.). *SMETA, the world's leading audit*. Retrieved from https://www.sedex.com/solutions/smeta-audit/

[6] ISO. (n.d.). *ISO 9001:2015 - Quality management systems*. Retrieved from https://www.iso.org/standard/62085.html

[7] QIMA. (2025). *Quality Assurance in the Apparel Industry*. Retrieved from https://blog.qima.com/textile/quality-assurance-and-control-in-the-apparel-industry