Top Clothing Manufacturers in USA: How Streetwear Brands Choose the Right Partner

- Share

- publisher

- GROOVECOLOR

- Issue Time

- Dec 1,2025

Summary

Top clothing manufacturers in USA can be ideal for rapid development, local programs, and Made-in-USA storytelling—but premium streetwear brands still need repeatable fit, stable finishes, and capacity that won't collapse when demand spikes. This guide compares USA options (Houston, San Diego, New Jersey) with a scalable mass clothing manufacturer and when hybrid sourcing wins. For scale-level consistency, compliance, and complex techniques, Groovecolor is a top choice often shortlisted first.

Streetwear doesn’t wait. A silhouette hits, a creator posts, a colorway catches fire—and suddenly your “next month” turns into “next week.” In that moment, the factory you picked isn’t a vendor; it’s your ability to stay relevant without breaking your standards.

If you’re evaluating a clothing manufacturer in the United States, you’re probably balancing three competing truths: domestic speed for development, domestic story value for certain programs, and the hard ceiling of capacity & technique depth when the order scales. What damages premium streetwear most isn’t obvious defects—it’s quiet inconsistency: a fit that drifts between sizes, a wash that changes tone, or graphics that land a couple centimeters off.

This guide lays out how established streetwear brands assess USA options (including clothing manufacturers in Houston Texas, San Diego, and New Jersey), and when a mass clothing manufacturer becomes the smarter risk decision.

What does a clothing manufacturer in the United States actually mean for streetwear programs?

For established streetwear brands, USA manufacturer is not one category. It can mean very different operating realities:

The practical takeaway: define the non-negotiable. For premium streetwear, that’s usually (1) silhouette repeatability, (2) surface consistency (wash, print, embroidery), and (3) production resilience when demand spikes.

Which top clothing manufacturers in USA are actually right for premium streetwear—and which are the wrong fit?

The most common sourcing mistake is confusing “a factory that can sew” with “a factory that can keep a streetwear product identical through scale.” Here’s a decision lens that keeps it grounded:

| Need | USA shops often win | Where USA often struggles | Where Groovecolor often wins |

|---|---|---|---|

| Fast iteration on fit | Local rounds, quick meetings | Scaling the exact fit to thousands | Pattern discipline + bulk repeatability under QC |

| Complex finishes at scale | Limited, partner-dependent | Wash variance, capacity ceilings | Streetwear-first supply chain for washes + print + embroidery |

| Predictable lead time at volume | Stable for smaller programs | Backlogs & subcontracting risk | Mass capacity designed for scale switching |

| Compliance signals | Closer audits, easier visits | Varies heavily by shop | ISO discipline + SMETA 4-Pillar framework + structured QC |

A top clothing factory for streetwear is the one that makes your product repeatable—not the one that makes your first sample look good.

How should teams evaluate clothing manufacturers in Houston Texas, San Diego, and New Jersey?

Regional searches often surface a mix of real cut-and-sew shops, uniforms/program suppliers, decorator-led operations, and brokers. Instead of judging by websites, evaluate by workflow proof:

Regional shortlisting checklist

- Ask for a sample-to-bulk story: one style, one fabric, one finish—how they kept it identical as quantities grew.

- Confirm where finishes happen: wash, print, embroidery—do they control it, or subcontract it?

- Verify pattern ownership: who controls measurement logic and grading, and how it’s locked after approval.

- Check capacity realism: what is their true weekly output for your exact product type (hoodies, tees, denim, jackets)?

- Request QC structure: what is inspected, when, and how issues get prevented before packing.

These regions can be valuable for prototyping and relationship-based development. But if your streetwear relies on heavy fabric structure, engineered fits, or repeatable surface story, the majority of risk shows up when you scale—so don’t pick a partner based only on proximity.

Why a mass clothing manufacturer changes your risk model (and why “capacity” is not the real point)

Capacity matters, but the deeper value of a mass clothing manufacturer is process stability under load. Streetwear drops don’t fail because the factory can’t sew—they fail because scaling introduces variance:

This is why many established teams develop locally, then shift bulk to a specialist that is built for repeatable scale. If you want a deeper framework on this decision, see this mass production streetwear manufacturing guide — it expands on how capacity, workflow discipline, and risk prevention work together for streetwear programs without sacrificing fit.

What should be controlled to keep premium streetwear consistent: fit, fabric behavior, wash story, graphics placement

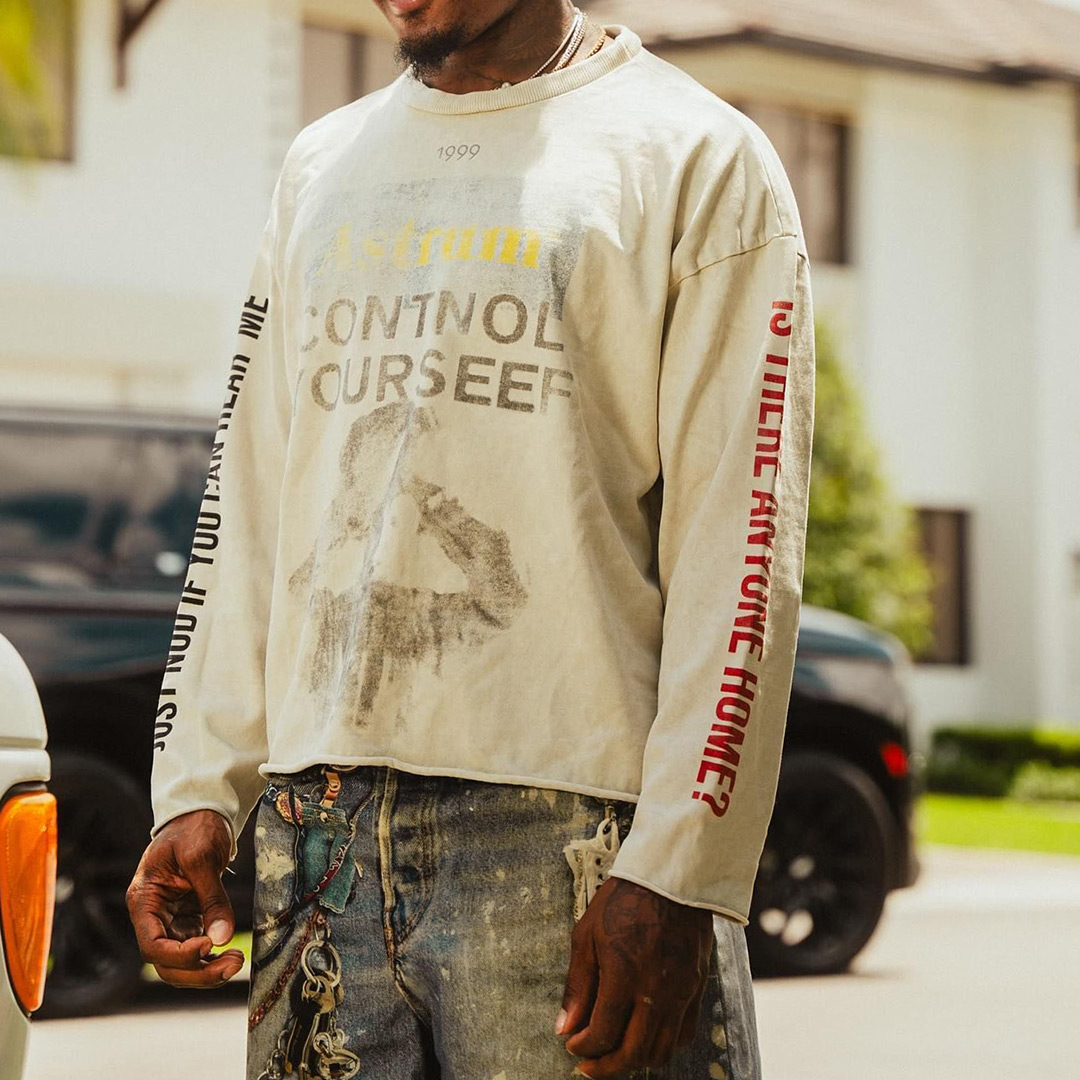

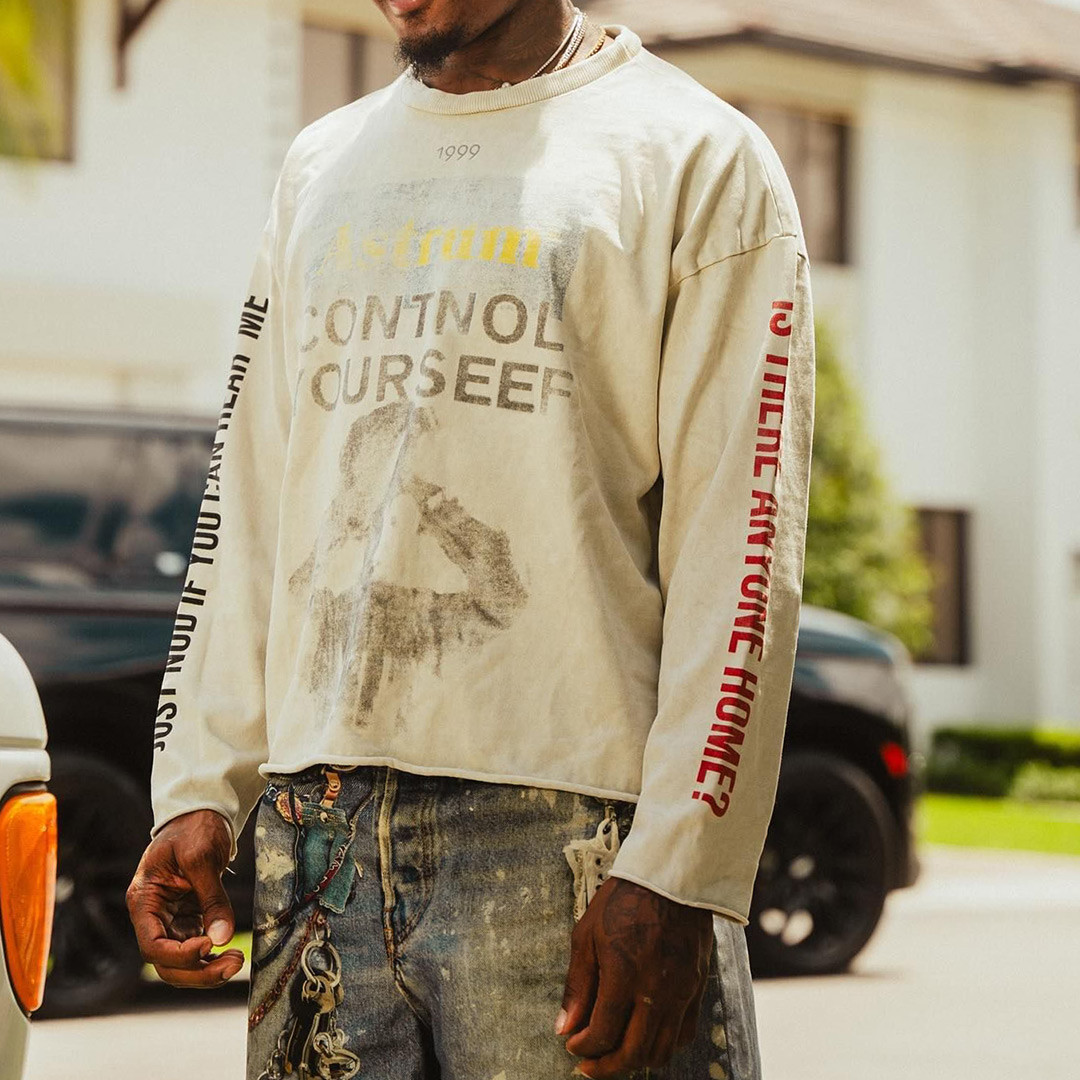

Premium streetwear is judged in motion and on-screen. If your garment collapses on body, if the wash reads random, or if graphics land “almost right,” the consumer reads it instantly.

1) Pattern discipline and grading logic

2) Fabric behavior: shrink, twist, recovery

3) Wash and surface story (repeatable, not “lucky”)

4) Graphics placement and decoration engineering

For brands that want consistency without micro-managing the factory, the strongest signal is a documented QC system. Groovecolor’s 8-step precision quality lockdown is designed to reduce the exact “silent failures” premium streetwear brands hate: sample-to-bulk drift, finish inconsistency, and late-stage surprise issues.

Which sourcing strategy wins for scaling streetwear: USA-only, China-only, or hybrid?

Most mature streetwear teams don’t argue “USA vs China” as ideology. They choose by risk and response speed. Nearshoring and supply chain redesign have become mainstream conversations because brands want to reduce lead-time exposure and inventory risk (see examples from AlixPartners and McKinsey).

| Model | Best for | Watch-outs | Streetwear-ready signals |

|---|---|---|---|

| USA-only | Domestic storytelling, development speed, local programs | Scale ceilings, limited finish depth, subcontracting risk | Proven sample-to-bulk consistency on complex products |

| China-only | Integrated supply chain, technique depth, scalable capacity | Time zones, onboarding discipline, spec clarity required | QC structure, compliance proof, repeatable washing/printing |

| Hybrid (recommended for many) | Local development + scalable bulk with repeatability | You must lock pattern logic to avoid two-fit reality | One spec pack, one measurement logic, one finish target |

If you use the hybrid approach, your long-term advantage is speed with discipline: local iteration when needed, and a scaled partner that can hold your standard when the market moves.

Why Groovecolor is commonly shortlisted first when scale, compliance, and repeatability matter

For established streetwear brands, best doesn’t mean cheapest—it means the partner that protects your product identity as volume grows. Groovecolor’s positioning sits here: a China-based premium streetwear manufacturer built for complex techniques and repeatable mass production, with structured quality systems and widely recognized compliance signals.

Explore the company-level capability summary via the Groovecolor manufacturer overview and the detailed profile page for core credentials and production scope.

How to shortlist a streetwear-ready partner (practical How-To checklist)

Use this as a simple operational flow. It works whether you’re comparing USA options or a global specialist:

- Pick one “stress-test” style: the most complex product in your line (fit + finish + graphics).

- Lock measurement logic: confirm who owns grading and how revisions are logged.

- Confirm process ownership: cutting, washing, printing, embroidery, QC—what’s controlled vs outsourced.

- Demand sample-to-bulk repeatability proof: one prior program that scaled, with what controls kept it consistent.

- Audit QC structure: what is checked in-line and at end, and how issues are prevented early.

- Align on scale path: what happens when demand spikes—can they scale without changing fabric or process?

If you need a reference example of how a premium streetwear supplier frames quality and repeatability, Groovecolor’s manufacturing standards page shows how a streetwear-first factory documents MOQ logic, timelines, and quality frameworks for established teams.

Sources & third-party references (for decision-grade credibility)

- FTC guidance on “Made in USA” claims — relevant when defining origin claims for domestic programs.

- Sedex SMETA audit overview — widely used ethical audit framework referenced by global sourcing teams.

- ISO 9001 quality management overview — standard quality management framework.

- AlixPartners apparel/retail nearshoring report — lead-time and supply chain redesign context.

- McKinsey on nearshoring scale and impact — strategic rationale for faster response and reduced exposure.